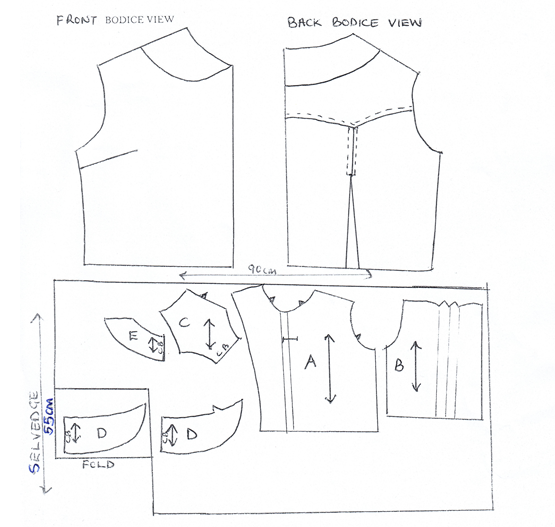

A pattern of a Childs bodice is provided.

You are advised to study the sketches, instructions and the layout before you begin the test.

Materials provided:

- PATTERN PIECES

- FRONT BODICE

- BACK BODICE

- BACK YOKE

- COLLAR

- BACKNECK FACING

- Plain lightweight cotton fabric 55cm by 91cm wide

- Sewing thread to match

- Embroidery thread (one to be used by all candidates)

- One large envelope.

THE TEST.

Using the materials provided, lay out, cut out and make THE LEFT HALF of Childs dress bodice to show the following processes;

- Cutting out 12 ½ mks

- Making the bust dart 8 mks

- Preparation and top stitching of inverted pleat 5 mks

- Attaching the back yoke to the back bodice and using the an overlaid seam (Neaten half of it) 8mks

- Preparation of machine fell seam on the shoulder 12mks

- Preparing the interfaced collar demonstrate snipping on the collar 6mks

- Joining the back neck facing to the extended front facing and using it to attach the collar (Neaten the free edges of facing) demonstrate snipping on neckline. 15mks

- Working an open seam on the side seam 9mks

- Working of the buttonhole with rounded ends 4mks

- Embroidering the scroll at the bodice front using chain stitches 6 ½ mks

MARKING SCHEME

a) Work well pressed(1)and folded ( ½ ) b) Lebel ( ½ )firmly sewn (1)without concealing details ( ½ ) and on single fabric ( ½ ) c) Pins/needles ( ½ ) unnecessary tacking threads ( ½ ) and loose threads ( ½ ) removed d) Made up for the left half (1) TOTAL |

MAX SCORE 1 ½ 2 ½ 1 ½ 1 |

SCORE |

|

6 ½ |

|

|

a) All five pieces cut out (5x ½ ) b) Smooth cutting of the front bodice and on straight grain (1)to within 3mm c) Smooth cutting of the back bodice (2)and on straight grain(1) d) Smooth cutting of the back yoke (2)and on grain (1)mark by impression e) Smooth cutting of the collar piece 3x ½ ( ½ ) and on straight grain (3x ½ ) ½ TOTAL |

2 ½ 1 3 3 3 |

|

|

12 ½ |

||

a) Straight stitchery (1) tapering to a point (1) b) Thread well fastened at the point c) Correct length of dart (8cm) from seamline to within 2mm (7.8-8.2cm) d) Correct width of dart (2cm) measured along the stitching to within 2mm e) Dart pressed flat (1) to waist line (1) TOTAL |

2 1 2 1 2

|

|

|

8 |

||

a) Top stitched (1) for 5cm (1)along its length (II) to within 2mm b) Both sides uniform width ½ x2 c) Neatly pressed and flat on R.S ( ½ ) +W.S ( ½ ) TOTAL |

2 2 1 |

|

|

5 |

||

a) Straight stitchery of the seam b) Evenness of the seam c) Flatness d) Neated halfway e) Using neat stitches (any) f) Seam firmed to 1cm before heating TOTAL |

2 1 1 1 2 1 |

|

|

8 |

||

a) Seam joined with straight stitchery b) Well neatened raw edges (1x2) c) Evennesss of seam allowance(2mks) d) Seam pressed open ( ½ x2) flat R.S ( ½ x2) e) Correct size of seam allowance (1cm) to within 2mm (0.8cm -1.2cm) ( ½ x2)

TOTAL

a) Back and extended front facing joined with straight stitchery ( ½ ) seam trimmed ( ½ ) pressed open ( ½ ) and unneated( ½ ) b) Facing attached to neckline with smooth stitchery c) Seam trimmed (1)snipped (2) and under stitched(2) d) Facing seam and shoulder seam meeting to within 2mm at neckline and shoulder seam (2) and held down with a stitch (1) e) Flatness of neck facing (front +back ) f) Free edge facing smoothly neatened g) Facing pressed flat TOTAL

a) Collar well pressed (knife edge) b) Collar seam allowance trimmed to 0.5cm(1) and snipped(mark by impression(1) c) Flat collar d) Well positioned at C.F

TOTAL

|

1 2 2 3 1

|

|

|

9 |

||

|

2 1 5 3 2 1 1

|

||

|

15 |

||

|

1 2 1 1 |

||

|

6 |

||

a) Button hole cut on grain b) Use of buttonhole stitches c) Use of overcasting stitches on rounded end d) Neat on the R.S ( ½ ) and the W.S ( 1/2 )

TOTAL |

1 1 1 1 |

|

|

4 |

||

a) Even stitches b) Correct tension c) Neat on R.S ( ½) + W.S ( ½ ) d) Reinforced at the beginning (½ ) and end (½)

TOTAL |

½ ½ 1 1 |

|

|

3 |

||

TOTAL GRAND TOTAL |

0 1 2 2 1 1 1 2 2 2 |

|

|

12 |

||

|

90MARKS |

Download HOME SCIENCE PAPER 2 - 2019 LAINAKU JOINT MOCK EVALUATION EXAMINATION.

Tap Here to Download for 50/-

Get on WhatsApp for 50/-

Why download?

- ✔ To read offline at any time.

- ✔ To Print at your convenience

- ✔ Share Easily with Friends / Students