INSTRUCTIONS TO CANDIDATES

- Write your name and index number in the spaces provided

- This paper consists of two sections: A and B. Answer all questions in section A and in Section B,Answer qn 11 and any other three in the spaces provided.

- All dimensions are in millimeters unless otherwise stated.

For examiner’s use only

|

Section |

Question |

Maximum score |

Candidates score |

|

A |

1-10 |

40 |

|

|

B |

11 |

15 |

|

|

12 |

15 |

||

|

13 |

15 |

||

|

14 |

15 |

||

|

15 |

15 |

||

|

Total score |

|||

Questions

-

- Give two reasons why one should study metalwork in high school. (2 marks)

- Give four factors influencing the choice of career of an individual. (2 marks)

-

- Give the three aspects of safety. (1 ½ marks)

- State one use of each of the following safety devices. (1 ½ marks)

- Leather gloves

- Clear goggles

- Helmet

- Give three differences between high carbon steels and high speed steels. (3 marks)

- Define the following mechanical properties of metals and give one example of a metal having such property . (6 marks)

- Hardness

- Malleability

- Toughness

- Plasticity

-

- Give two uses of screw threads. (2 marks)

- Give four points to observe in care for taps and dies. (2 marks)

- Give the steps followed when carrying out the following finishing processes. (4 marks)

- Bluing

- Oil blacking

-

- Define the term soft soldering. (1 mark)

- Name the following in soft soldering and give the use of each in order to obtain a sound soldered joint. (3 marks)

- Filler metal

- Flux

- Heat source

- What causes the following defects during riveting? (4 marks)

- Rivet bends

- Loose riveted joint

- Plate split

- Gap left between plates

-

- Give two uses of a pair of dividers as a metalworking tool. (2 marks)

- What type of hacksaw blade is recommended for a school workshop? Give a reason for your choice. (2 marks)

-

- State two uses of a cutting fluid in metal cutting. (2 marks)

- What is used for marking the following in sheet metalwork? (2 marks)

- Folding lines

- Cutting lines

SECTION B

This section consists of four questions, attempt question 11 and any other three questions

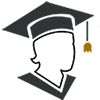

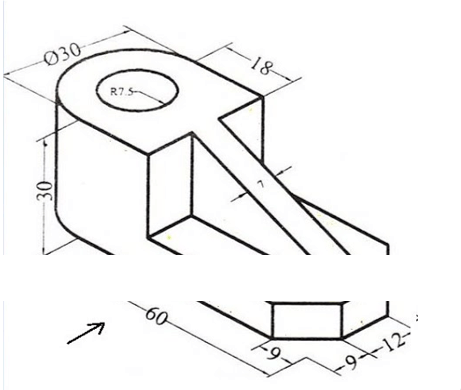

- The fig below shows a machined block drawn in first angle orthographic projection, draw full size the block isometric ( 15 marks)

-

- Explain the following heat treatment processes (6 marks)

- Hardening

….……………………………………………………………………………………………… - Tempering

….……………………………………………………………………………………………… - Annealing

….………………………………………………………………………………………………

- Hardening

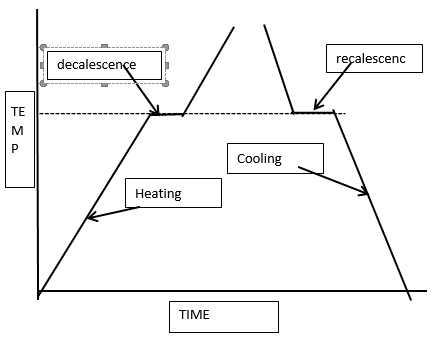

- Use a graph to explain the behavior of steel when heated. (6 marks)

- List three methods of checking furnace temperatures when carrying out heat treatment (3 marks)

- Explain the following heat treatment processes (6 marks)

-

- Outline the procedure of lighting a blow pipe. (5 marks)

- Give four functions of flux in brazing (4 marks)

- Use labelled sketches to show the difference between rightward and leftward welding technique. (4 marks)

- List four factors that affects the quality of a brazed joint (2 marks)

-

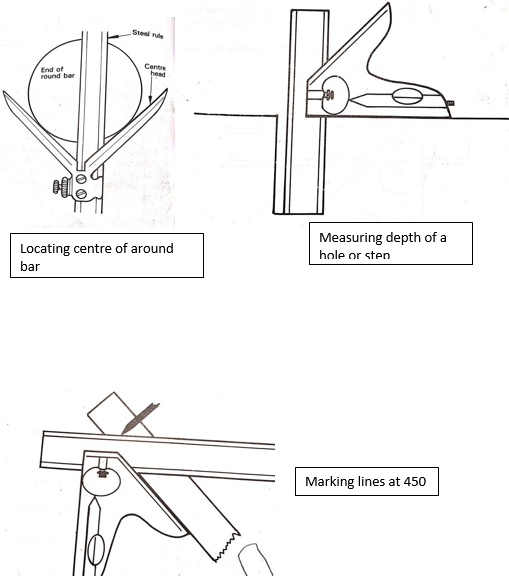

- State and explain four parts of a combination set (4 marks)

- Use sketches to show four uses of a combination set. (6 marks)

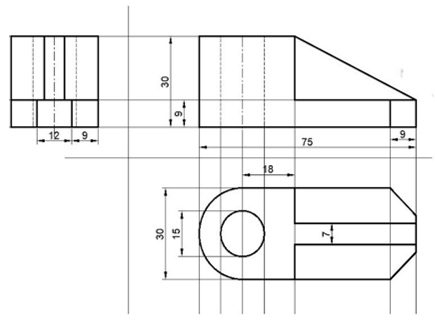

- Below is a diagram of a tool used in measuring, give the reading shown in the instrument. (2marks)

- State three care for each of the following (3 marks)

- Micrometer screw gauge

- Vernier caliper

-

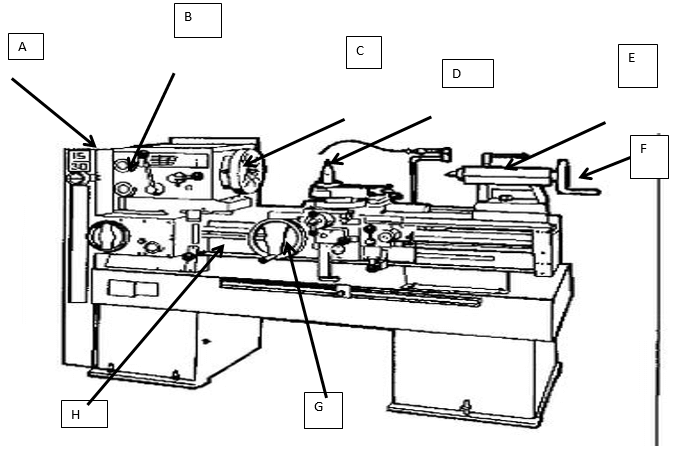

- Figure 4 shows a diagram of a lathe machine

Name the parts labelled A, B, C, D, E, F, G and H. (3 marks)- ……..................................

- ……..................................

- ……..................................

- ……..................................

- ……..................................

- ……..................................

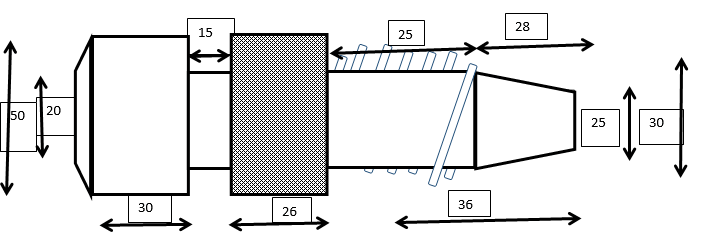

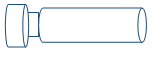

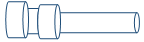

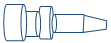

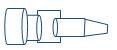

- Explain the procedure of making the component shown (12 marks)

- Figure 4 shows a diagram of a lathe machine

MARKING SCHEME

-

- Two reasons why one should study metalwork in high school. (2mks)

- Get an understanding of the place of metalworking industries which contribute to the growth of our nation.

- Develop skills in the safe use and care of materials.

- Apply skills learned in other subjects.

- Learn to work and live with others.

- Acquire information to assist one to explore careers.

- Make functional articles of one’s interest and appreciate them.

- Four factors influencing the choice of career of an individual. (2mks)

- Dictates of the environmental conditions where one lives

- Career inclination

- Educational background

- Availability of training opportunities

- Availability of jobs

- Two reasons why one should study metalwork in high school. (2mks)

-

- The three aspects of safety. (1 ½ mks)

- Personal safety

- Tool and equipment safety

- Environmental safety

- Use of each of the following safety devices. (1 ½ mks)

- Leather gloves

Protect the hands when handling rough or hot workpieces. - Clear goggles

Protect the eyes from flying chips. - Helmet

Protect the head from being hit by falling objects.

- Leather gloves

- The three aspects of safety. (1 ½ mks)

- Give three differences between high carbon steels and high speed steels. (3mks)

High carbon steel

High speed steel

Not resistant to corrosion

Resistant to corrosion

Cheaper

More expensive

Cannot retain hardness at high temp

Retain hardness at high temp

- Define the following mechanical properties of metals and give one example of a metal having such property . (6mks)

- Hardness

It is the ability of a metal to resist scratching,indentation or wear by abrasion by other hard bodies.e.g high carbon steel,high speed steel,cast iron - Malleability

It is the property of a metal that allows it to be hammered or rolled without cracking e.g aluminium,brass,copper,mild steel. - Toughness

It is the ability of a metal to resist fracture or deformation when subjected to blows. e.gmedium carbon steel - Plasticity

It is the property that makes a metal to remain deformed after the load has been removed e.g lead,copper,gold.

- Hardness

-

- Two uses of screw threads. (2mks)

- Transmission of motion

- Joining parts together.

- Give four points to observe in care for taps and dies. (2mks)

- They should not be given undue pressure.

- High temp may make the tools soft and useless.

- They must be lubricated when in use.

- The correct sizes of tap wrenches and diestock should be used.

- The correct sizes of holes and rods to be threaded are essential.

- Taps and dies should be cleaned,oiled and kept in the screw plate after use.

- Two uses of screw threads. (2mks)

- Give the steps followed when carrying out the following finishing processes. (4mks)

- Bluing

- Clean with an abrasive cloth

- Heat with a clean flame until it turns blue

- Dip in clean light oil

- Wipe with a clean cloth after it has cooled.

- Oil blacking

- Clean with an abrasive material

- Heat to red hot

- Coat with clean heavy lubricating oil or linseed oil

- Heat for 5-10 mins to about 200°c to burn off excess oil.

- Wipe clean with cotton waste.

- Bluing

-

- Define the term soft soldering. (1mk)

- It is a low temp thermal joining process.

- Name the following in soft soldering and give the use of each in order to obtain a sound soldered joint. (3mks)

- Filler metal

- Soft solder-joining the metals.

- Flux

- Resin,zinc chloride-cleaning agent

- Heat source

- Jiko/stove,electricity-heating the metals and solder.

- Filler metal

- Define the term soft soldering. (1mk)

- What causes the following defects during riveting? (4mks)

- Rivet bends

- Too large hole,too much shank projection

- Loose riveted joint

- Inefficient hammer blows

- Plate split

- Rivets not spaced well on the plate.

- Gap left between plates

- Drilling burrs not removed.

- Rivet bends

-

- Two uses of a pair of dividers as a metalworking tool. (2mks)

- Transferring measurements from a steel rule to a workpiece and vice versa.

- Drawing arcs and circles on metals.

- What type of hacksaw blade is recommended for a school workshop? Give a reason for your choice. (2mks)

- Flexible because it cannot break easily.

- Two uses of a pair of dividers as a metalworking tool. (2mks)

-

- State two uses of a cutting fluid in metal cutting. (2mks)

- Cooling the work and the tool.

- Lubricating the tool.

- What is used for marking the following in sheet metalwork? (2mks)

- Folding lines

- Pencil/brass scriber

- Cutting lines

- Steel scriber.

- Folding lines

- State two uses of a cutting fluid in metal cutting. (2mks)

-

-

- heat treatment process

- Hardening-this is heat treatment process which makes steels with sufficient carbon content harder by heating uniformly to temperature above upper critical temperature and then cooling suddenly

- Tempering -this is a heat treatment process carried out on hardened steels to remove excess hardness and relief stress by heating it to temp below critical point and cooling in water

- Annealing-this is a heat treatment process carried out to relieve internal stress caused by work hardening .its carried out by reheating steel to temperature above the critical temperature and then allow it to cool slowly in a closed furnace

Correct stating 3×1/2=21/2mrks

Correct explanation 3×1=3MRKS

- Behavior of steel when heated

- When steel is heated temperature raises uniformly to 7250c and then remains stationary for a while, it then raises at a slower rate to 8000c.

- On cooling the temperature drops to 725 and then remains stationary for a while then continues to drop uniformly

Correct explanation 2×1/2=1MRKS

Correct curves 2×2=4MRKS

Correct critical temp points 2×1=2mrks

- methods of checking furnace temperature

- By use of pyrometers

- By use oh ceger cones

- By observing temperate changes 3×1=3mrks

- heat treatment process

-

- lighting a blow pipe

- Open the acetylene valve half turn and oxygen valve full turn,ensure needle valves are closed

- open the acetylene needle valve and using acetylene regulators set the required working pressure then close

- Open oxygen needle valve an using oxygen regulators set the required working pressure then close

- Open acetylene needle valve slightly and light the torch,increase the amount of gas until the flame is clear of soot

- Open the oxygen needle valve and set the required flame Correct statement of point

5×1=5mrks

- Functions of flux

- To make the filler metal flow easily in to the joint

- Remove oxides

- Prevent further oxidation 3×1=3mrks

- Rightward welding technique

Leftward welding technique

Correct diagram 2×2=4mrks

Factors affecting the quality of a brazed joint- The joint design

- Type of filler rod used

- Amount of heat supplied

- Types of flux used

- The gap left between plates 4×1=4mrks

- lighting a blow pipe

-

- parts of a combination set

- Steel rule- its is made of hardened steel and has a groove along one side to accommodate various heads

- Centre head- has two arms which forms angles of 450 on either sides of the steel rule, it is used to locate the center of round bar

- Square head-the head makes an angle of 90 and 45 on either sides to the steel rule, it is used to check angles of 90 and 45

- Protractor heads-has a protractor dial which measures angles from 0-180 to the steel rule

Correct stating 3×1/2=11/2mrks

Correct explanation 3×1=3mrks

- uses of a combination set

Correct diagram 3×1=3mrks

Correct naming 3×1/2=11/2mrks - Vernier caliper reading

MSR=5.00

VSR=5×0.02

=0.1

ADD 5.00 ± 0.1

=5.1cm

Correct MSR 1/2mrk

Correct VSR 1MRK

Correct addition 11/2mrk - Care of micrometer screw gauge

- It should not be dropped

- It should not be held in the hand for along time

- It should be stored in its case after use

- It should be cleaned and oiled after use

- Care of vernier calipers

- It should not be dropped

- It should be cleaned and oiled after use

- They should not be piled together

- The clamping screw should always be in position

3×1/2=11/2

3×1/2=11/2

- parts of a combination set

-

- parts of lathe

- A-Head

- B-Speed change gear levers

- C-Chuck

- D-Tool post

- E-Tail stock

- F-Tail stock hand wheel

- G-Carriage hand wheel

- H-Feed shaft 8×1/2=4mrks

- Procedure of making component

-

step

procedure

illustration

1

Cut the round bar required

2

Hold the round bar in the three jaw chuck and set it to run true

3

Face the end

4

Parallel turn the work piece to diameter 50

5

Part off slightly 70mm from the end for 15mm to diameter 30mm

6

Parallel turn a length of 63mm from the end to diameter 30mm

7

Taper turn a distance of 28mm from the end to diameter 25

8

Cut threads from 28mm 60 63mm

9

Drill a hole of diameter 20mm and bore it to diameter 23mm

10

Part off the work piece

11

Set the work piece on the lathe machine and chamfer the other end

- parts of lathe

Download Metalwork P1 Questions and Answers - Wisdom Pre-Mock Form 4 Exams 2021/2022.

Tap Here to Download for 50/-

Get on WhatsApp for 50/-

Why download?

- ✔ To read offline at any time.

- ✔ To Print at your convenience

- ✔ Share Easily with Friends / Students