Instructions

- Answer all questions in section A ,Answer question 11 and any other three questions in section B in the space provided.

- ALL dimensions are in millimeters unless otherwise stated.

Questions

-

- Define the terms metals and metalwork. (2marks)

- Name any four careers in the field of metalwork. (2marks)

-

- Name the three aspects of safety. (1 ½ marks)

- List any five safety rules in a metal workshop. (2 ½ marks)

-

- Metal cutting tools should be made using hard materials.Explain why and name those two metals. (2marks)

- Give two differences between Steel and aluminium. (2marks)

-

- The figure shows a tool used in measuring and checking.

- Give the name of the tool and name the material used for making it. (2marks)

- Give two uses of the tool. (2marks)

- The figure shows a tool used in measuring and checking.

-

- Why is the cutting edge of a cold chisel hardened while the end struck by a hammer tempered. (2marks)

- The figure below shows a tool used in cutting metals.

- Name the problem that the tool has ,state the cause of it and explain how to correct it. (2marks)

- The figure below shows a metal cutting tool.

- Give the name of the tool and its use. (2marks)

- State two reasons for notching edges of sheet metal. (2marks)

- List all the steps followed in order to come up with a snap head on a rivet. (4marks)

-

- List four methods of applying paint. (4marks)

- State two advantages of using a hacksaw over a cold chisel in cutting metals.(2marks)

- Give four uses of templates in metalwork. (4marks)

- What care should be taken of the combination set? (4marks)

Section B (60marks)

Answer question 11 and any other three questions in this section

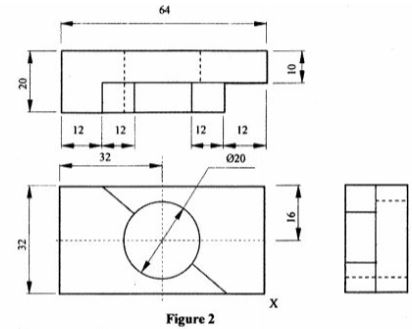

- Figure 2 shows orthographic views of a machined block drawn in third angle projection.

On the grid paper provided, draw the isometric view of the block taking X as the lowest point.

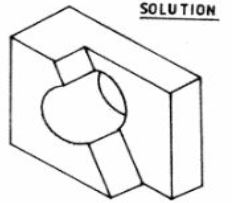

Show three main dimensions. (15 marks) - Two mild steel plates of thickness 3mm are to be riveted using double riveted lap joint.

- Draw the sectional front elevation and plan of the riveted joint. (6marks)

- Calculate the rivet diameter (2marks)

- Calculate the rivet shank projection for a snap head ( 2marks)

- Calculate the distance between two rivets (2marks)

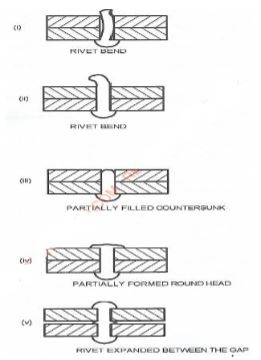

- Use sketches to show three rivet defects ( 3marks)

-

- Explain three inventories in the workshop (3marks)

- Explain the following documents as used in a workshop (3marks)

- Invoice

- Catalogue

- Delivery note

- Explain step by step the procedure of recruiting an employee in a company (6marks)

- what do you understand by the term “break even” ( 1mark)

- State two advantages of partnership business ( 2marks)

-

- differentiate oil blacking from bluing (2marks)

- Explain painting as a finishing process ( 2marks)

-

- Differentiate tears from runs ( 2marks)

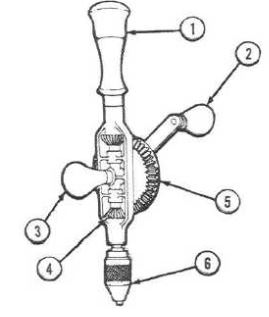

- Use sketch to describe a hand drill (4marks)

- State and explain four types of cold chisels ( 4marks)

- Differentiate morse tapered twist drill from a parallel shank twist drill ( 1mark)

-

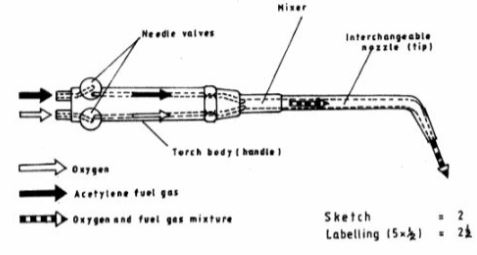

- Sketch a gas welding torch and:

- label five parts; (5marks)

- state four precautions to be observed when handling it. (3 marks)

-

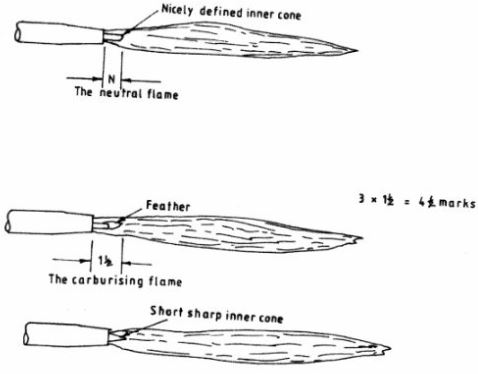

- Use labelled sketches to show the three types of gas welding flames. (3marks)

- Explain how each of the flames is obtained. (3marks)

- Sketch a gas welding torch and:

Marking Scheme

-

- Define the terms metals and metalwork. (2mks)

- Metals are hard solids mined from the ground.

- Metalwork is the art of making articles from metal.

- Name any four careers in the field of metalwork. (2mks)

- Artisan,craftsmanship,technician,engineer,technologist.

- Define the terms metals and metalwork. (2mks)

-

- Name the three aspects of safety. (1 ½ mks)

- Personal safety,tool and equipment safety and environmental safety.

- List any five safety rules in a metal workshop. (2 ½ mks)

- Use proper personal protective equipment.

- Do not run in the workshop.

- Horse play should be avoided.

- Workshop floors should always be clean.

- Use gangways when walking in the workshop.

- Name the three aspects of safety. (1 ½ mks)

-

- Metal cutting tools should be made using hard materials.Explain why and name those two metals. (2mks)

- So as to resist being cut,scratched or dented/So as to cut other metals without themselves being cut. HCS,HSS

- Give two differences between Steel and aluminium. (2mks)

Steel Aluminium Strong Weak Rusts/can easily be corroded Resistant to rust/corrosion

- Metal cutting tools should be made using hard materials.Explain why and name those two metals. (2mks)

-

- The figure shows a tool used in measuring and checking.

- Give the name of the tool and name the material used for making it. (2mks)

- Odd-leg calipers-HCS

- Give two uses of the tool. (2mks)

- Marking lines parallel to given datum edge.

- Finding the centre of a round bar.

- Give the name of the tool and name the material used for making it. (2mks)

- The figure shows a tool used in measuring and checking.

-

- Why is the cutting edge of a cold chisel hardened while the end struck by a hammer tempered. (2mks)

- The cutting edge is hardened to prevent wearing,being cut and dented.

- The end struck by a hammer is tempered to absorb the shock from the hammer blow.

- The figure below shows a tool used in cutting metals.

- Name the problem that the tool has ,state the cause of it and explain how to correct it. (2mks)

- Mushroom head-Caused by repeated hammering making the material of the head to build up.Removed by grinding it off/dressing then chamfered.

- Name the problem that the tool has ,state the cause of it and explain how to correct it. (2mks)

- Why is the cutting edge of a cold chisel hardened while the end struck by a hammer tempered. (2mks)

- The figure below shows a metal cutting tool.

- Give the name of the tool and its use. (2mks)

- Countersink bit-Producing a conical hole at the mouth of a round hole.

- State two reasons for notching edges of sheet metal. (2mks)

- To improve appearance

- To prevent overlaps.

- Give the name of the tool and its use. (2mks)

- List all the steps followed in order to come up with a snap head on a rivet. (4mks)

- Mark out the holes and other details on one of the plates.

- Clamp the plates together and drill one hole through both plates.

- Cut the rivet to length holding the waste shank in the vice.

- Using the dolly,close the plates together.

- Make the rivet expand in the hole using the flat face of the hammer.

- Form the head using pein end of the hammer.

- Finish forming the head using the snap.

- Remove the unwanted excess material using a file.

-

- List four methods of applying paint. (4mks)

- Using a brush

- Spraying using a spray gun.

- Dipping in paint.

- Using a piece of cloth.

- State two advantages of using a hacksaw over a cold chisel in cutting metals.(2mks)

- It gives a good surface finish.

- It is more accurate.

- List four methods of applying paint. (4mks)

- Give four uses of templates in metalwork. (4mks)

- Marking out repeated identical parts.

- Checking angles,curves and contours

- Marking out and guide for drill bit.

- Guide for oxy-acetylene cutting.

- What care should be taken of the combination set?

- Should be cleaned well after use

- Should be oiled lightly before being kept to prevent corrosion.

- Avoid dropping or knocking the tool against other hard objects.

- Excessive pressure should not be applied.

- The tool is best stored in a box or special bag.

Section B

-

-

-

- d=11/2t

11/2 × 3=4.5 mm - shank projection = 11/2 d

11/2×4.5=6.75 mm - distance between rivets= 3D

3×4.5=13.5mm -

-

-

-

- permanent inventories- record of all machines,equipment and furnaces that ate permanent in workshop

- expandable inventories- record of all tools and items that wear out with time

- Consumable inventories -record of materials that ate completely used up in workshop

-

- invoice- a document sent to the buyer listing all items and the prices that a buyer wishes to buy

- Catalogue- a document sent by seller listing all items in stock and their prices

- Delivery note - a document sent together with items bought listing all items packed and delivered

-

- identification of gap in the firm

- Getting the required minimum qualifications

- Advertising for the vacancy

- Delimiting a pool of potential employees

- Conducting an interview

- Induction of the new employee

- a situation in the business where the business in not making any profit or loss.

-

- easy to raise capital

- Labour is shared

- Easy to expand

- Provides variety of prepossession and abilities

-

-

- oil blacking is carried out by heating metal to red hot and then wiped with a rag dipped in heavy lubricating oil while in bluing the metal is heated in clean flame and dipped in clean light oil

-

- clean the article to be painted with abrasive material

- Apply primer and give it time to dry

- Apply under coat and give it time to dry

- Apply top coat and give it time to dry

- tears are droplets of pain running down the article while rune ate the lines made by droplets of excess paint

-

-

- flat cold chisel- used for general purpose

- Cross-cut cold chisel-used for making square grooves

- Half round cold chisel- used for making circular grooves

- Vee-shaped cold chisel-used for making vee shaped grooves

-

- Welding torch

Safety precautions- Ensure that the nozzle seat and threads are free from any foreign materials.

- Nozzle should only be cleaned with tip cleaner

- Never use nozzle to hold or push the Work piece

- Avoid knocking nozzle against hard surfaces

Any 3 x 1 = 3 marks

- Gas welding flames

-

-

- Neutral Flame has equal quantities of oxygen and acetylene

- Carburising flame has more acetylene gas than oxygen

- Oxiding flame has more as oxygen than acetylene gas

3 x 1

-

- Welding torch

Download Metal Work Paper 1 Questions and Answers - Bunamfan Cluster Pre Mock Exam 2022.

Tap Here to Download for 50/-

Get on WhatsApp for 50/-

Why download?

- ✔ To read offline at any time.

- ✔ To Print at your convenience

- ✔ Share Easily with Friends / Students