QUESTIONS

SECTION A (40 marks)

Answer all the questions in this section in the spaces provided.

-

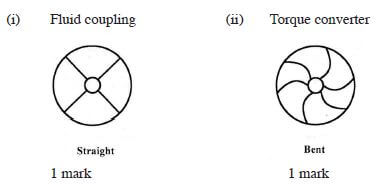

- Outline six key steps in the entrepreneurship process.(3 marks)

- List four areas where ventilation is necessary in a power mechanics workshop.(2 marks)

-

- State two ethical conducts to be observed by a power mechanics technician. (1 mark)

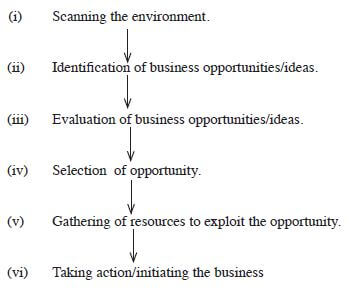

- Make a free-hand sketch of a self-tapping screw.(2 marks)

- Outline four constructional differences between a four stroke single cylinder SI engine and a four stroke single cylinder C.I engine.(4 marks)

-

- State two advantages of air brakes over hydraulic brakes.(2 marks)

- Explain why:

- the split washer has offset ends;(1 mark)

- the tab washer has a square projection on the inner edge.(1 mark)

-

- State two possible causes for a faint horn sound.(2 marks)

- List two operational differences between the DC generator and the alternator.(2 marks)

-

- Explain the term "spring weight" as applied to leaf springs.(2 marks)

- With respect to a single cylinder engine, differentiate between "make" and "model".(2 marks)

-

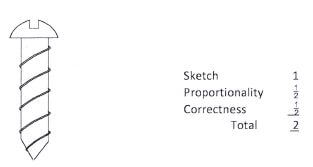

- With the aid of a sketch, illustrate the type of tyre wear pattern caused by under inflation.(1 mark)

- Explain the following properties of ferrous metals:

- toughness;(1 mark)

- hardness.(1 mark)

-

- State two functions of the fuel tank cap on a single cylinder engine.(2 marks)

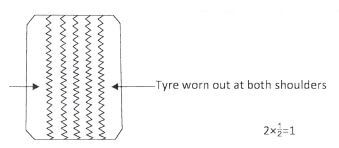

- With the aid of diagrams, illustrate the difference between the vanes of a fluid coupling and a torque converter.(2 marks)

-

- Name four types of pliers.(2 marks)

- List four thermal processes used for joining metals.(2 marks)

-

- Distinguish between the two types of engine block construction.(2 marks)

- Explain the meaning of steering geometry".(3 marks)

SECTION (60 marks)

Answer question 11 and any other three questions from this section in the spaces provided.

Candidates are advised not to spend more than 25 minutes on question 11.

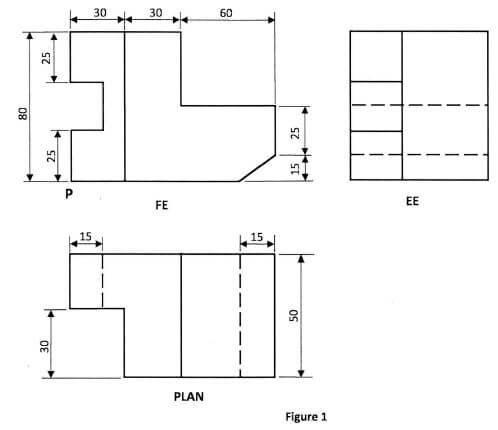

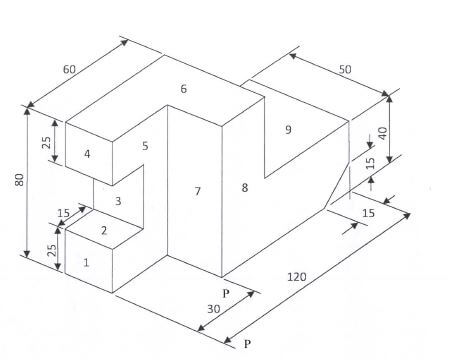

- Figure 1 shows three orthographic views of a block drawn in first angle projection.

On the grid paper provided draw the block FULL SIZE in isometric projection taking P as the lowest point.(15 marks) -

- List the accessories and equipment used in arc welding,(5 marks)

- Outline the procedure for arc welding a butt joint.(10 marks)

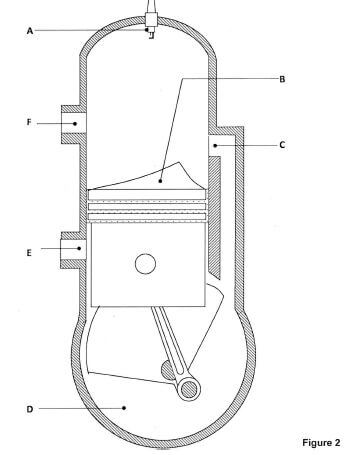

- Figure 2 shows the three point type of a 2-stroke cycle petrol engine.

- Name the parts labelled A to F.(3 marks)

- Explain how the engine operates.(12 marks)

-

- The oil pressure warning light of a vehicle remains on when the engine is running. Outline three checks that may be performed on the lubrication system to establish the cause of the fault.(3 marks)

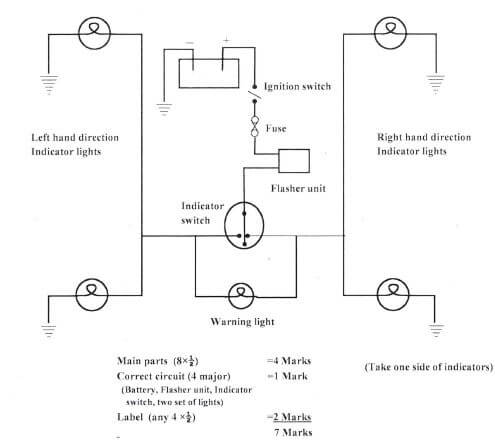

- With the aid of a circuit diagram, explain the operation of a two terminal flasher unit.(12 marks)

-

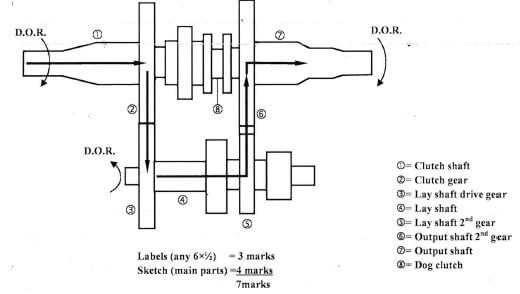

- Name four types of gears.(2 marks)

- Name two functions of a gear box in a vehicle.(2 marks)

- With the aid of a labelled sketch, explain the power flow in a three-speed sliding mesh gearbox engaged in second gear.(11 marks)

MARKING SCHEME

-

-

6 x 1/2 = 3 marks -

- Battery charging area.

- Engine testing area.

- Welding area.

- Storage area.

- Drainage area.

4 x 1/2 = 2 marks

-

-

- Ethical conducts for a power mechanic technician

- Honesty.

- Integrity.

- Professionalism.

- courtesy.

- Timeliness

Any 2 x 1/2 = 1 mark

-

- Ethical conducts for a power mechanic technician

-

CI SI Injector Spark plug Pressure ignited (no magnet) Magneto. Unit injection system Carburetor Fuel/line High tension lead 4 x 1/2 = 2 marks 4 x 1/2 = 2 marks -

-

- Air brake equipment are cheap to produce since they do not required high degree of accuracy.

- Air brakes are relatively cheaper to maintain.

- Compressed air can be used for other vehicle application.

Any 2 x 1 = 2 marks

-

- Split washer has offset ends - to ensure that the bolt is tightened. The extra force exerted to flatten the offset ends prevents the nut or bolt from working loose.

- Tab washer has a square projection fitted into the edge to prevent washer from turning thus keeping the nut tight despite the turning motion. Any 2 x 1 = 2 marks

-

-

-

- Faulty connection.

- Loose connection.

- Out of adjust.

- Dirty contacts.

Any 2 x 1 = 2 marks

-

- DC generators delivers direct current while alternator delivers alternating current.

- DC generator spins the armature (output) coils inside two or more stationery field coils while the alternator spins the field coils inside a set of stationery stator windings (out put).

- Alternator delivers high current at low engine speeds than DC generators. It is more efficient at low speeds.

Any 2 x 1 = 2 marks

-

-

-

- The weight carried by the leaf 1 spring ie. body weight and the load 1 . Any 2 x 1 = 2 marks

-

- Make refers to the commercial name of the engine eg. Clinton, Honda, Briggs etc manufacturer. 1

- Model refers to the code the manufacturer gives to a specified type of engine eg. Clinton 494, Honda G35. 1

Any 2 x 1 = 2 marks

-

-

-

2 x 1/2 = 1 marks -

- Toughness - ability to resist change of shape without fracture when sufficient force is applied. 1 mark

- Hardness - ability to resist penetration or change of shape until fracture occurs. 1 mark

-

-

-

- Prevents dust and dirt or any other foreign material from entering the tank.

- Allows tank to be filled with fuel and prevent fuel from splashing out of the tank.

- Allows atmospheric pressure to push fuel from the tank to the carburettor when the engine is operating.

Any 2 x 1 = 2 marks

-

-

-

-

- Diagonal/side cutter.

- Combination pliers.

- Long nose pliers.

- Slip joint pliers.

- Vice grip pliers.

- Circlip pliers.

Any 4 x 1/2 = 2 marks

-

- Soft soldering.

- Hard soldering (brazing)

- Arc welding.

- Gas welding.

- Spot welding.

Any 4 x 1/2 = 2 marks

-

-

-

- Integral 1/2 - block and crank case are moulded together. 1/2

- Separate 1/2- block and crank case are separate. 1/2

-

- Steering geometry describes various angles formed by the front wheel alignment set up 1/2. It comprises caster 1/2 camber 1/2, toe-in 1/2, king pin inclination 1/2 toe out 1/2 among others.

Any 6 points x 1/2 = 3 marks

- Steering geometry describes various angles formed by the front wheel alignment set up 1/2. It comprises caster 1/2 camber 1/2, toe-in 1/2, king pin inclination 1/2 toe out 1/2 among others.

-

-

- 9 faces = 9 x 1 - 9 marks

- Point P - 1 mark

- Isometric figure - 1 mark

- Groove - 1 mark

- Chamfer - 1 mark

- Scale - 1 mark

- Tidiness - 1 mark

15 marks

-

-

- Welding machine (either DC or AC).

- Two cables.

- Electrode holder.

- Ground clamp.

- Head shield.

- Welding shield.

- Asbestos gloves.

- Leather apron.

- Wire brush.

- Chipping hammer.

- Tongs.

Any 10 x 1/2 = 5 marks

-

- Clean and prepare the joint. 1

- Position the joint on welding table. Use clamps if necessary. 1

- Attach the ground cable securely.1/2

- Set the welding machine to the desired amperage. 1

- Wear protective clothing and head shield. 1

- Clamp the electrode in the electrode holder at 90o to the jaws. 1/2

- Lower your head shield and strike the arc, using the scratch method. 1

- Tack both ends of the butt joint with a weld spot. 1

- Starting from one side, continue welding, maintaining the correct arc length (about 1 to 3 mm) and speed to avoid the electrode sticking to the joint until the joint is fully welded. 2

- Through the shield, watch the puddle of molten metal directly behind the arc. It should be in form of a ridge when it solidifies, implying the correct speed. 1

-

-

-

- A - Spark plug.

- B - Deflector crown.

- C- Transfer port.

- D- Airtight crankcase.

- E - Inlet port.

- F - Exhaust outlet port.

6 x 1/2 = 3 marks

- Upward stroke. 7 marks

- Piston is at bottom dead centre (B.D.C.) 1/2, inlet port is closed 1/2 and exhaust 1/2 and transfer port are open. Exhaust gases 1/2 are leaving the cylinder and a compressed charge 1/2 of fresh mixture is entering at the transfer port on the opposite side of the cylinder. The deflector crown on the piston is shaped so as to deflect fresh mixture to the top of the cylinder while at the same time directing exhaust gases to the exhaust gases. 1 As the piston moves 1/2 moves further up the cylinder, it seals off the transfer 1/2 and exhaust ports, thus compressing 1/2 the mixture 1 at the combustion when it nears TDC. At the same time, this upward movement uncovers the inlet 1/2 port to allow fresh mixture 1/2 to be drawn into the crankcase by the partial vacuum created by the upward movement of the piston.

Downward stroke - The expansion of the burning mixture forces the piston to move down and rotate the crankshaft 1 . At the same time, the descending piston covers the inlet 1/2 port and begins to reduce the effective volume of the 1/2 crankcase. This action compresses the mixture in the crankcase until the transfer port is 1 uncovered to let some of this mixture to escape to combustion chamber via the transfer 1/2 port. Further downward 1 movement uncovers the exhaust port allowing exit 1/2 of the combustion gases. 1/2 The process is then repeated.5 marks

- Piston is at bottom dead centre (B.D.C.) 1/2, inlet port is closed 1/2 and exhaust 1/2 and transfer port are open. Exhaust gases 1/2 are leaving the cylinder and a compressed charge 1/2 of fresh mixture is entering at the transfer port on the opposite side of the cylinder. The deflector crown on the piston is shaped so as to deflect fresh mixture to the top of the cylinder while at the same time directing exhaust gases to the exhaust gases. 1 As the piston moves 1/2 moves further up the cylinder, it seals off the transfer 1/2 and exhaust ports, thus compressing 1/2 the mixture 1 at the combustion when it nears TDC. At the same time, this upward movement uncovers the inlet 1/2 port to allow fresh mixture 1/2 to be drawn into the crankcase by the partial vacuum created by the upward movement of the piston.

-

-

- Check if:

- there is sufficient oil.

- the gauge is faulty.

- relief valve is faulty.

- oil filter is chocked/clogged.

- oil pump is faulty (seized).

- oil pump is worn out.

6 points x 1/2 = 3 marks

-

- In the indicator switch LHS 1/2flasher unit, the current flow through the fuse in the flasher unit is 1/2 low and therefore lights do not 1/2 show. This current however heats the wire and allows it to expand 1/2 thus closing the contacts 1/2.

- Current will then flow through the LHS to the indicator 1 lamps which will eventually light. On the warning light circuit the current flows through the RHS of flasher 1/2 indicator to the ground but since it is low it does not light the RHS lamps 1 .

5 points x 1 = 5 marks

- Check if:

-

-

- Spur gear.

- Helical gear.

- Double helical gear.

- Hypoid gear

- Bevel gear.

- Worm gear.

Any 4 x 1/2 = 2 marks

- Functions of gearbox:

- provide reverse gear

- vary torque and speed as per road and load conditions.

- provide neutral gear.

Any 2 x 1 = 2 marks

-

Explanation 4 marks- To obtain 2nd gear.

- The low and reverse manishaft gear is disengaged from the low speed counter shaft gear and shiffed to the neutral position.

- 2nd speed gear manishaft is shiffed to the second speed positopm to mesh with the second countershaft gear.

-

Download KCSE 2014 Power Mechanics Paper 1 Questions with Marking Scheme.

Tap Here to Download for 50/-

Get on WhatsApp for 50/-

Why download?

- ✔ To read offline at any time.

- ✔ To Print at your convenience

- ✔ Share Easily with Friends / Students