QUESTIONS

SECTION A (40 marks)

Answer all questions in this section in the spaces provided.

- State four factors that one should consider when choosing a career.(2 marks)

-

- Outline four factors that would help an entrepreneur to decide on the type of metalwork business to establish.(2 marks)

- State four factors to be considered when tempering steel.(2 marks)

-

- State four safety precautions to be observed in a metal workshop. (2 marks)

-

- Name one solvent commonly used in paints.(1 mark)

- State two functions of solvents in paints.(2 marks)

-

- Outline two factors to consider when planning and designing a metallic component.(1 mark)

- State four pieces of information included in a cutting list.(2 marks)

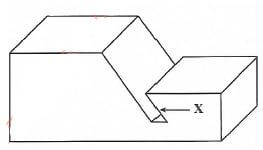

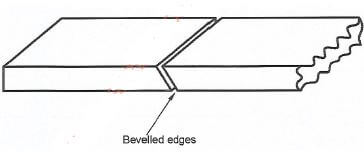

- Figure 1 shows two metal pieces joined together, leaving a gap marked X.

Figure 1

Outline the procedure of determining the size of the gap.(3 marks) -

- Name three tools used with a surface plate stating one function of each.(3 marks)

- State the function of each of the following parts of a lathe machine.(3 marks)

- Carriage wheel

- Cross-slide wheel

- Half-nut lever

-

- Give one reason why each of the following dies would be preferred over the others:(3 marks)

- Split die

- Solid die

- Two piece die

- Use a sketch to show how strength of a butt joint can be increased when brazing.(2 marks)

- Give one reason why each of the following dies would be preferred over the others:(3 marks)

-

- Define the term "notching" as used in sheet metalwork.(1 mark)

- State two reasons for notching. (1 mark)

- State one factor that determines the size on an overlap when joining metals. (1 mark)

-

- Outline the steps to be followed when drilling a pair of plates for riveting. (3 marks)

- Explain each of the following terms as used in forging:(3 marks)

- Piping

- Necking

- Hardie

- Give three reasons for each of the following:(3 marks)

- Using proper clothing when arc welding.

- Checking the surface after laying the first bead in arc welding

SECTION B (60 marks)

Answer question II on the A3 paper and any other three questions from this section in the spaces provided. Candidates are advised to spend not more than 25 minutes on question 11.

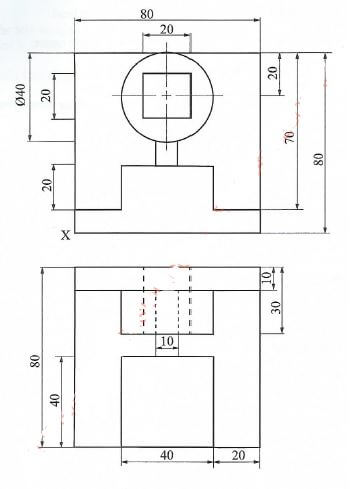

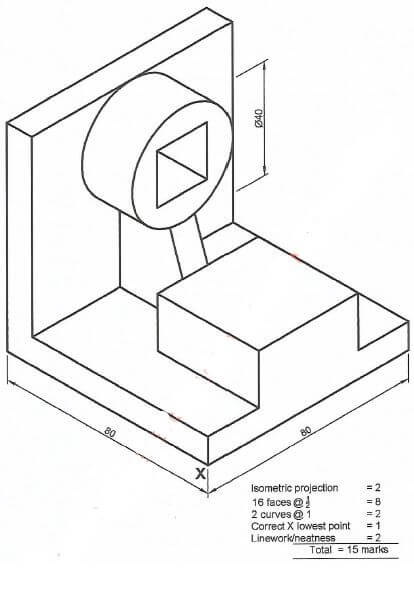

- Figure 2 shows two orthographic views of a block drawn in first angle projection.

Figure 2

Draw the block Full Size in isometric projection, taking X as the lowest point. (15 marks) -

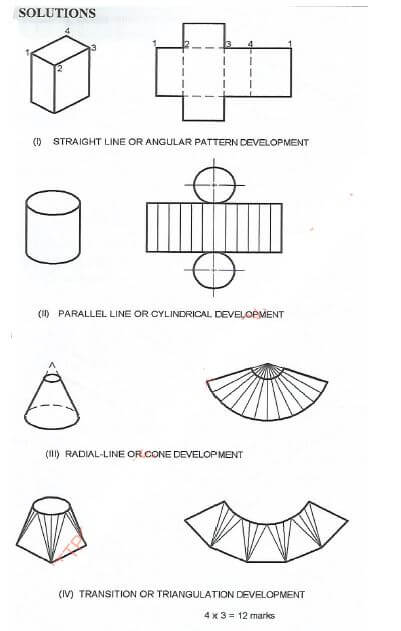

- With the aid of sketches, describe four types of pattern developments.(12 marks)

- Outline three main points to note when developing patterns.(3 marks)

-

- State the material to be used to rivet a pan made of aluminium, stating the reason for the choice.(1 mark)

- Two mild steel plates, 3 mm thick are to be joined using mild steel rivets. Determine each of the following:(6 marks)

- The rivet shank diameter.

- The projection allowance required to form a snap head.

- The distance between the edge of the plate and hole centre.

- The distance between two rivets.

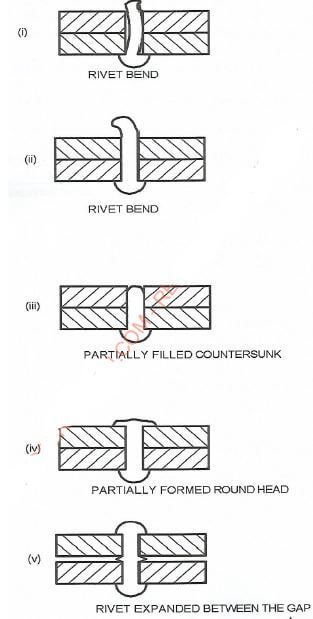

- Use sketches to show four types of defects which may occur during riveting. (8 marks)

-

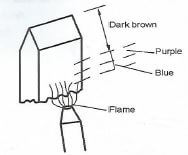

- Using a sketch, describe how the flame should be applied to the point of a cold chisel when tempering(6 marks)

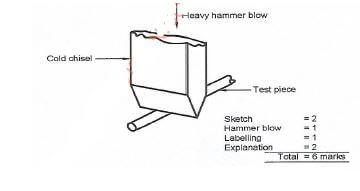

- With the aid of a sketch, show how a hardened and tempered tool can be tested before putting it into use.(6 marks)

- Outline three methods used to check the correct temperature when hardening steels.(3 marks)

-

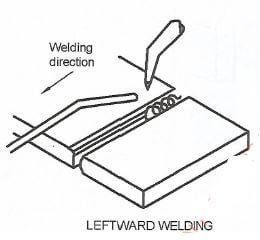

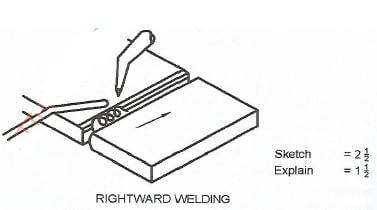

- With the aid of sketches, describe each of the following methods of arc welding(8 marks)

- Leftward welding

- Rightward welding

- Give three common methods used in each of the following weld tests:(3 marks)

- Non-destructive

- Destructive

- State four advantages of using rightward welding method.(4 marks)

- With the aid of sketches, describe each of the following methods of arc welding(8 marks)

MARKING SCHEME

-

- The diversities of the environmental conditions where an individual lives.

- The career inclination of an individual.

- The individual's basic educational background.

- The available training, opportunities.

- The availability of jobs in the country.

-

-

- The observations one has made.

- The advice received from those with experience.

- The knowledge and skills one has.

- The initiative one has.

- The articles which will likely sell and satisfy the needs of the consumers.

- Amount of capital

- Availability of materials

- Infrastructure and services available

-

- The type of tool or article to be made from the steel and their functions

- The degree of hardness/toughness that the tool must receive in order to function properly.

- The colour of oxide films

-

-

-

- Use equipment you are familiar with, if in doubt ask.

- Do not use faulty equipment.

- Handle equipment carefully.

- Clean and oil equipment after use.

Accept any other correct response

-

- Turpentine

- -As a thinner, making the paint less thick thus improve workability.

-Clean the brush after use.

-

-

-

- The amount of material required.

- The cost involved.

- The availability of materials.

-

- The type of material required.

- The number of pieces of a particular part required.

- Actual sizes, including cutting allowances for each piece.

- Description of each part.

-

-

- Clean the blades.

- Choose the blade or combination of blades that fit the gap snuggly.

- Add the readings for each leaf to obtain the size of the gap.

-

-

- Scribing block or surface gauge- Used for scribing lines at given heights.

- Angle plate - used for supporting work being marked.

- Vee block - used for holding round work pieces when marking or drilling

-

- Carriage wheel - For moving the carriage along the bed which allows for parallel turning.

- Cross slide wheel - For moving the compound rest perpendicular to the bed.

- Half-nut lever - engages the carriage to the lead screw for thread cutting.

-

-

-

- Permits a little adjustment in its size.

- It can cut fine threads on large diameters.

- It is excellent in rethreading damaged screws or bolts.

-

The surface to be brazed can be increased by beveling the edges and hence increase the strength of the joint.

Sketch-1

Explain - 1

-

-

- Notching means cutting or removing metal from comers of sheet metal before folding or forming.

- Notching is done to:

- Prevent overlaps.

- Improve the appearance of the end product.

- For safety

- The size of the overlap depends on the following:

- Size of the article to be made.

- Thickness of the material

- Strength of joint

-

-

- Mark out the holes and other details on one of the pieces

- Clamp the plates together using a hand vice.

- Drill one hole through both plates, the size of the rivet shank.

-

- Attempting to draw down a point in the round results in the tip becoming hollow and weak.

- Necking - Forming rounded grooves in metals.

- Hardie - the bottom tool when one is forging using a pair of tools.

-

-

-

- Use of proper clothing provides protection against

- Sparks

- excessive heat

- агс гays

- Use of proper clothing provides protection against

- Check the surface for

- Evenness of the surface.

- Improve skirting and stopping

- Proven fusion

-

-

-

-

- POINTS TO NOTE WHEN DEVELOPING PATTERNS.

- Allowances for edges, seams and hems must be provided.

- While some pattern are directly made on the sheet materials, others While some are done on papers and transferred by carbon or tracing with a scriber or a dot punch.

- Where many articles of the same kind are to be made, a template is made of metal. The templates can be held firmly on sheet metal and can be traced.

-

-

- Aluminium

Reason - the choice of the material depends on the materials to be joined. -

- Rivet shank diameter D - 11/2t

where t = material thickness.

Therefore, D=11/2 x 3 = 3/2 x 3 = 9/2=41/2 mm - Projection to have a snap head - 11/2D

= 3/2 x 9/2 = 27/4 = 63/4 mm - Distance from edge to hold centre = 11/2D

= 3/2 x 9/2 = 27/4 = 63/4 mm - Distance between 2 rivets = 3D

= 3 x 9/2 = 27/2 = 131/2mm

Calculations 4x 11/2= 6 marks

- Rivet shank diameter D - 11/2t

- Riveting defects

- Aluminium

-

-

-

- The flame is positioned as shown in the sketch because if it is applied directly onto the cutting edge, rapid heating on the outside surface takes place. This causes the formation of oxide films while the inner structure of the steel is relatively not heated and therefore not tampered. The edge of the chisel will therefore be liable to shatter immediately it is subjected to pressure or blows.

Sketch - 3 marks

Explanation - 3 marks

6 marks

-

-

If the hardening and tempering have been done properly, there will be no damage to the tool -

- Observing the correct colour which is usually cherry red.

- A magnet, where the steel is heated until there is no magnetic attraction. This is because steel loses its magnetism at the critical temperatures.

- A pyrometer, which is an electric thermometer attached to the furnace to give correct temperatures of the heating chamber.

-

-

- SOLUTION

-

This type of welding technique refers to the method of holding the blow pipe in the right hand, the filler rod in the left hand, and moving in a leftward direction. In this technique, the filler rod precedes the blow pipe in the direction of travel. -

The weld is started at the left hand side to the right side and the torch always precedes the filler rod in the direction of travel.

-

-

- Common methods in non-destructive testing

- Visual inspection.

- Penetrate fluid.

- Application of load.

- Radiography

- Magnetic dusting

- Common methods is destructive testing

- Bending

- Tensile

- Impact

- Application of a load

- Common methods in non-destructive testing

- Advantages of rightward welding method:

- It is faster than leftward welding.

- Less gas is used when welding.

- No bevel is required for steels up to 8mm, so less filler metal is used.

- Because the flame is always facing the weld, the cooling rate is lower, so the weld is more ductile.

- SOLUTION

Download KCSE 2018 MetalWork Paper 1 with Marking Scheme.

Tap Here to Download for 50/-

Get on WhatsApp for 50/-

Why download?

- ✔ To read offline at any time.

- ✔ To Print at your convenience

- ✔ Share Easily with Friends / Students