SECTION A (40 marks)

Answer all the questions in this section in the spaces provided.

-

- List four functional requirements of a woodwork workshop. (2 marks)

- State three causes of accidents relating to the use of hand tools in a woodwork workshop. (3 marks)

- Explain the cause of each of the following classes of fire:

- Class A fire (2 marks)

- Class B fire (2 marks)

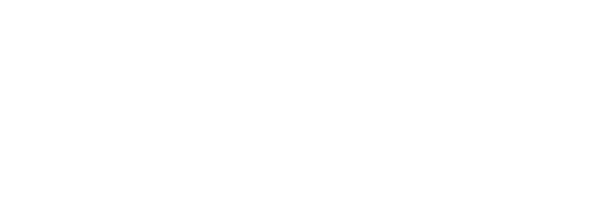

- Figure 1 shows a vernier calliper reading. (2 marks)

Determine the value of the reading. - State four practices that demonstrate the proper use of a cross-cut saw when cutting timber. (4 marks)

-

- State two functions of the knob on a bench plane. (2 marks)

- Sketch the plan of the head to show the shape of the slots on the following types of screws:

- Philips recess (2 marks)

- Allen recess (2 marks)

-

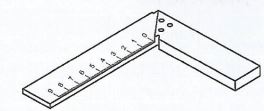

- Sketch and label a try square. (2 marks)

- State two uses of a try square. (2 marks)

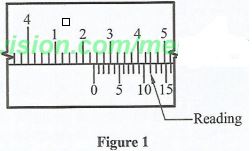

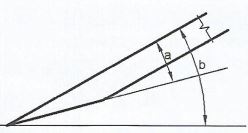

- Figure 2 shows the cutting edge of a chisel.

- Name the angles labelled a and b. (1 mark)

- Give the recommended value for each of the angles in 7(a). (2 marks)

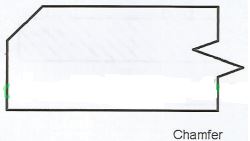

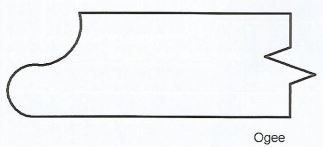

- Sketch each of the following types of treatment given to the edges of tables: (3 marks)

- Chamfer

- Ogee

- State four characteristics of varnish applied on a dry wooden surface. (4 marks)

- Print the phrase "Practice makes perfect" using the vertical capital letters of uniform 5 mm height and word spacing of 5 mm. (5 marks)

SECTION B (60 Marks)

Answer question II on A3 paper and any other three questions from this section in the spaces provided. Candidates are advised not to spend more than 25 minutes on question 11.

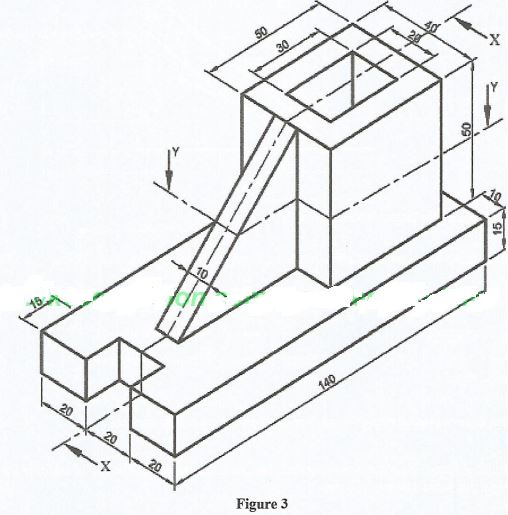

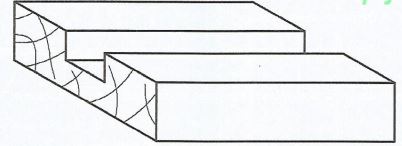

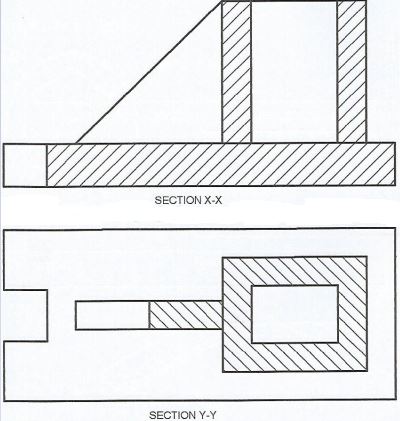

- Figure 3 shows a machine drawn in isometric projection.

Draw the following views of the component Full Size in first angle projection: (15 marks)- Sectional front elevation along the cutting plane X-X.

- Sectional plan along the cutting plane Y-Y.

-

- State four factors to consider when choosing a finish for a wooden item. (4 marks)

- Outline the procedure of measuring, marking and fitting a mortise lock on a kitchen cabinet door. (11 marks)

-

- State three advantages of plain sawn timber over quarter sawn timber. (3 marks)

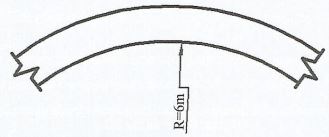

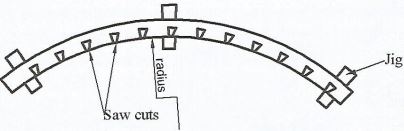

- Figure 4 shows the plan of a curved timber piece.

With the aid of a sketch, outline the procedure of kerf bending to produce the curved piece. (12 marks)

-

- State two functions of the cap iron in a jack plane. (2 marks)

- Figure 5 shows a wooden block with a groove 12 mm wide and 20 mm deep.

Outline the procedure of marking and cutting the groove using a rebate plane. (7 marks) - Explain two methods of testing a planed timber face for straightness and flatness. (6 marks)

-

- State two uses of a nail punch. (2 marks)

- Outline the procedure of sharpening a chisel using an oilstone. (5 marks)

- Describe the following natural adhesives, giving one characteristic of each:

- Animal glue (3 marks)

- Case-in (3 marks)

- Blood glue (2 marks)

MARKING SCHEME

| NO | DESCRIPTION | MARKS |

| SECTION A | ||

| 1 |

|

2 marks

3 marks |

| 2 |

Classes of fire

|

4 marks |

| 3 |

Vernier Caliper reading Steel rule reading: 4 main units - 4 x 10 = 40.00 mm 1⁄2 2 sub units 2 = 2.00 mm 1⁄2 1 intermediate 1 x 0.25 = 0.25 mm /1⁄2 Vernier scale reading: 11 units = 0.11 1⁄2 Total = 42.36 mm = 4.236 cm |

2 marks |

| 4 |

Practices that demonstrate proper use of cross-cut saws:

|

4 marks |

| 5 |

|

2 marks

4 marks |

| 6 |

Try square

|

2 marks

2 marks |

| 7 |

Cutting edge of a chisel:

|

1 mark

2 marks |

| 8 |

|

3 marks |

| 9 |

Characteristics of varnish:

|

4 marks |

| 10 |  |

5 marks |

| SECTION B | ||

| 11 |  SECTION Y-Y

|

15 marks |

| 12 |

|

4 marks

11 Marks |

| 13 | ||

|

3 marks

4 marks

8 marks |

|

| 14 |

|

2 marks

7 marks

6 marks |

| 15 |

|

2marks

5 marks

3 marks

3 marks

2 marks |

Download Woodwork Paper 1 Questions and Answers - KCSE 2021 Past Papers.

Tap Here to Download for 50/-

Get on WhatsApp for 50/-

Why download?

- ✔ To read offline at any time.

- ✔ To Print at your convenience

- ✔ Share Easily with Friends / Students