SECTION A (40 marks)

Answer all questions in this section in the spaces provided.

-

- Give two reasons for studying metalwork in secondary school. (2 marks)

- Distinguish between the two types of prices in buying and selling of goods. (2 marks)

-

- State the importance of following the correct procedure when carrying out a task in the workshop. (1 mark)

- State the precaution to be taken when lifting heavy loads manually. (2 marks)

-

- Explain the use for marking agents in metalwork. (2 marks)

- Give two examples of marking agents. (1 mark)

-

- Outline the procedure of checking a surface for flatness using a straight edge. (3 marks)

- With reference to markking out:

- Define the term "datum".

- State two ways of minimising parallax error when using a scriber.

- State three common causes of blade breakage when cutting using a hacksaw. (3 marks)

-

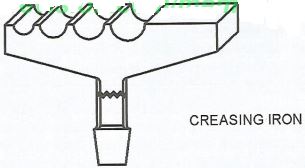

- Sketch a creasing iron and give two uses of the iron. (3 marks)

- Outline the procedure of separating a countersunk riveted joint. (3 marks)

-

- Give one reason for doing each of the following:

- Cooling brazed joint in air rather than water

- Packing the work with fire bricks while brazing (2 marks)

- State the reason for doing each of the following in gas-welding: (3 marks)

- Manipulating the torch

- Cracking the equipment

- Using flux

- Give one reason for doing each of the following:

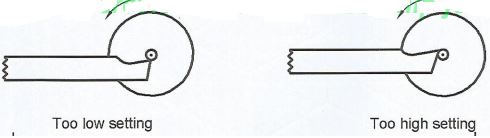

- Use sketches to show the effects of each of the following when facing on a lathe: (4 marks)

- Setting the tool too high

- Setting the tool too low

- Explain each of the following terms as applied in heat treatment of steel: (3 marks)

- Lower critical point

- Upper critical point

- Critical range

-

- State two reasons for upsetting a metal bar prior to bending. (3 marks)

SECTION B (60 marks)

Answer question 11 on the A3 paper provided and any other three questions from this section in the spaces provided. Candidates are advised to spend not more than 25 minutes on question 11.

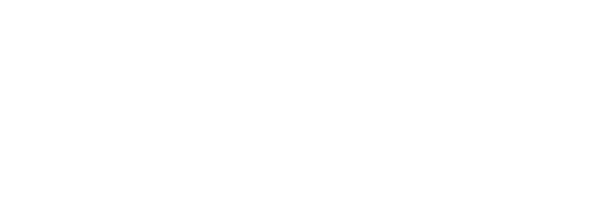

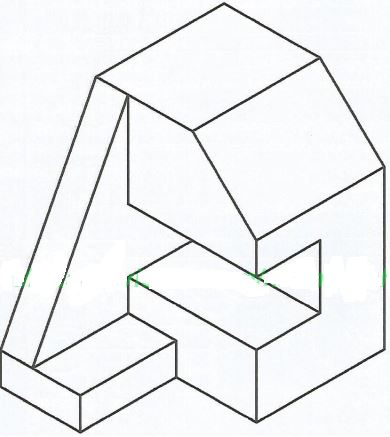

- Figure 1 shows three orthographic views of a block drawn in first angle projection. Draw the block Full Size in isometric projection

(15 marks). -

- State two advantages of each of the following types of drills: (4 marks)

- Parallel shank drills

- Taper shank drills

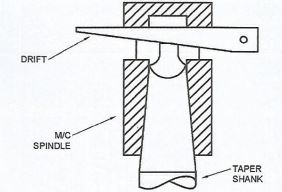

- With the aid of sketches, show the use of a drift in drilling. (5 marks)

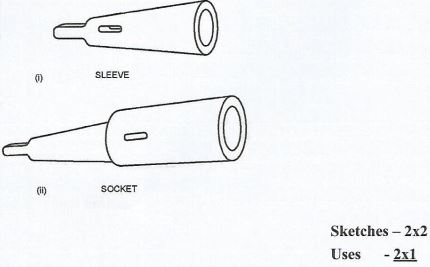

- Sketch the following drilling accessories and explain the use of each: (6 marks)

- Drill sleeve

- Drill socket

- State two advantages of each of the following types of drills: (4 marks)

-

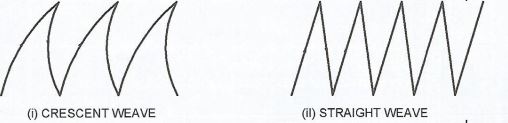

- Sketch each of the following patterns as used in arc welding: (4 marks)

- Crescent weave

- Straight weave

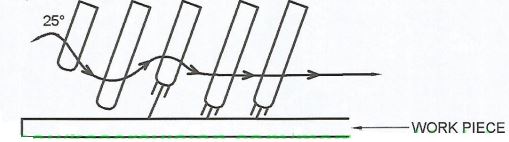

- Illustrate the movement of the electrode when starting a weld using the tap method. (3 marks)

-

- State two reasons for testing a welded joint (2 marks)

- Explain three methods of testing a welded joint. (6 marks)

- Sketch each of the following patterns as used in arc welding: (4 marks)

-

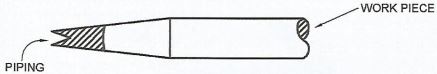

- Illustrate the piping effect in forging. (2 marks)

-

- Outline the steps to follow in eliminating the piping effect. (4 marks)

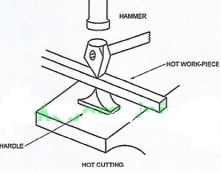

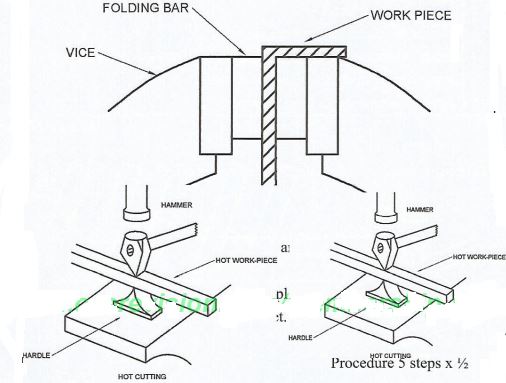

- With the aid of sketches, show the difference in the use of a cold chisel and a hot chisel. (6 marks)

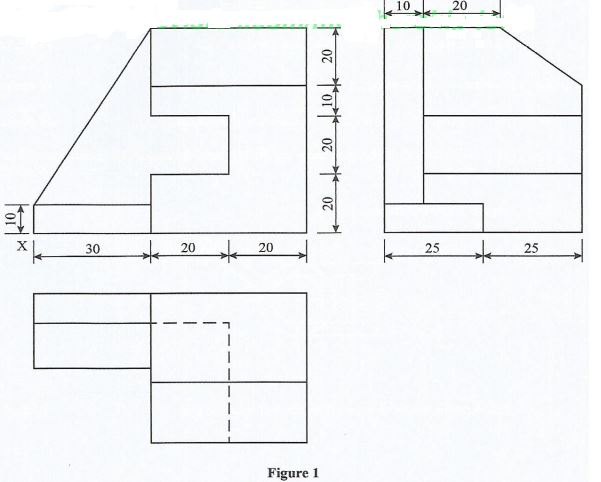

- Figure 2 shows a forged eye.

Calculate the length of material required to form the eye. (3 marks)\

-

- Give three reasons for using beaded edge on sheet metal articles. (3 marks)

- With the aid of sketches, outline the procedure of making a beaded edge. (5 marks)

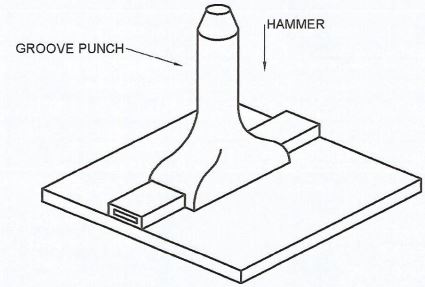

- Sketch to show a grooved punch in use. (3 marks)

- Outline the procedure of soldering seams to make them water tight. (4 marks)

MARKING SCHEME

| SECTION A | ||

| 1 |

|

(2marks)

(2marks) |

| 2 |

|

(1 mark) (2 marks) |

| 3 |

|

(2 marks)

(1 mark) |

| 4 |

|

(3 marks)

(3 marks) |

| 5 |

Reasons for blade breakage.

|

(3 marks) |

| 6 |

|

(2 marks)

(1 mark)

(3 marks) |

| 7 |

|

(2 marks)

(3 marks) |

| 8 |  (b) (a) In either case, a small pip will be left at the centre of the faced end. (2 x 2) |

(4 marks) |

| 9 |

Explanation of terms.

|

(3 marks) |

| 10 |

|

(3 marks) |

| SECTION B | ||

| 11 |  M/S 12 faces @ 1= 12 marks Scale -1 Isometric - 1 Line work -1 Total = 15 marks |

|

| 12 |

|

2 marks

2 marks

5 marks

4 marks

|

| 13 |

|

4 marks

(3 marks)

(2 marks)

(6 marks) |

| 14 |

|

(2 marks)

(4 marks)

(6 marks)

(3 marks)

|

| 15 |

|

(3 marks)

(2½marks)

(3 marks)

(4 marks) |

Download Metalwork Paper 1 Questions and Answers - KCSE 2021 Past Papers.

Tap Here to Download for 50/-

Get on WhatsApp for 50/-

Why download?

- ✔ To read offline at any time.

- ✔ To Print at your convenience

- ✔ Share Easily with Friends / Students