Questions

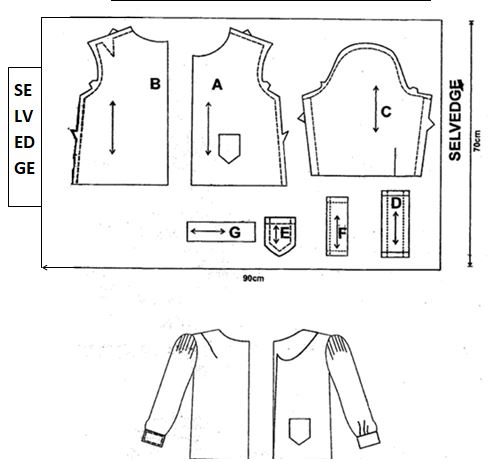

A pattern of a child’s dress is provided. You are advised to study the sketches, instructions and the layout well before you begin the test.

MATERIALS PROVIDED:

- Pattern pieces for the dress:

A – Dress front

B – Dress back

C – Sleeve

D – Cuff

E – Pocket

F – Cuff interfacing

G – Sleeve opening binding

- Plain light weight cotton fabric 70cm long by 90cm wide.

- Cotton sewing thread to match the fabric.

THE TEST:

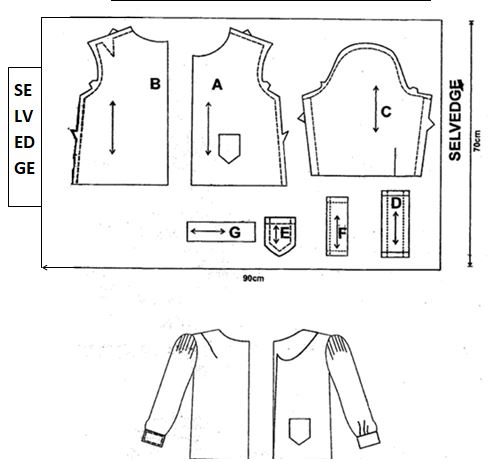

Using the materials provided cut out and make the LEFT HALF of the child’s dress to show the following:

- The working of the shoulder dart.

- The preparation and attachment of the pocket.

- The joining of the shoulder seam using a neatened plain seam.

- The joining of the side seam using a neatened open seam.

- The making of the bound opening of the sleeve.

- The joining of the under arm seam using a French seam.

- The preparation and attachment of an interfaced cuff.

- The preparation and attachment of the sleeve, without trimming the seam allowance.

At the end of the examination, firmly sew onto your work, on a single fabric, a label bearing your name and index number. Remove the needles and pins from your work, and then fold your work neatly

THE LAYOUT IS NOT DRAWN TO SCALE

Marking Scheme

| |

PRESENTATION |

TOTAL MARKS |

ACTUAL SCORE |

REMARKS |

| 1 |

- Work well pressed (½) and well folded (½)

- Label firmly sewn on a single fabric

- Unnecessary temporary stitches, threads and pins removed

- Made up left half 1

|

1

1½

1½

1 |

|

|

| |

|

5 |

|

|

| 2 |

Cutting out and graining

- All the seven pieces cut out (Back, front, sleeve, cuff, cuff facing, opening strip and pocket) ½x7

- CB smoothing cut (1) and straight grain to within 2mm(1)

- CF smoothing cut (1) and straight grain to within 2mm (1)

- Smoothing lower edge cut,

- Bound opening strip cut on bias (1)

|

3½

2

2

1 |

|

|

| |

|

10½ |

|

|

| 3 |

Pocket

- Hem appropriately finished (raw edge well neatened)

- Even width of the folded part 1

- Pocket sides well tacked under 1

- Pocket fixed with straight stitchery

- Pocket stitchery pivoted at the corners (1/2×3)

- Pocket mouth well reinforce (1/2×3)

- Flatness of the pocket RS (1/2) and WS (1/2)

- Size (1) and shape (1) of the pocket

- Superimpose the pattern pocket to within 3mm

|

1

1

1

1

1½

1½

1

2

1 |

|

|

| |

|

11 |

|

|

| 4 |

Shoulder dart

- Straight stitchery (1) tapering to nothing (1/2)

- Threads ends well fastened at the tip

- Correct length of the dart (5 1/2 cm) to within 3mm measuring from first stitching line

- Correct width of the dart (6mm) to within 2mm measured from first stitching line at shoulder seam.

- Dart pressed towards CB and flat at the right side.

- Flatness of the dart RS(1/2) and WS(1/2)

|

1½

1

1

1

1

1 |

|

|

| |

|

6½ |

|

|

| 5 |

Side seam (open seam) if not award zero

- Joined with straight stitchery

- Quality of neatening (1x2)

- Flatness of the seam at the armhole RS 2

- Evenness of the neatened seam allowance

|

1

2

2

2 |

|

|

| |

|

7 |

|

|

| 6 |

Shoulder seam (plain seam)

- Seam joined with straight stitching line

- Well neatened raw edges (1/2×2)

- Evenness of the neatened seam (1×2)

- Flatness of the seam at the armhole RS(1/2) and WS(1/2)

|

1

1

2

1 |

|

|

| |

|

5 |

|

|

| 7 |

Sleeve

- Good hang

- Well distributed gathers at the sleeve head

- Dress and sleeve notches matching at front (1/2) and at the back (1/2)

- Underarm seam (French) well – trimmed (i.e. no threads on RS)

- Underarm seam made with straight stitchery

- First stitching line made straight (1) mark by impression and seam well knife edged (1)

- Evenness at the seam (1) width and appreciate size (1) of the width (0.6 – 1cm)

- Seam pressed towards back at cuff (1/2) and arm hole(1/2)

- Flatness of the seam at cuff(1/2) and armhole (1/2) WS(1/2) and RS(1/2)

- Side seam and underarm seam meeting within 2mm

|

1

2

1

1

2

2

2

1

2

1 |

|

|

| |

|

15 |

|

|

| 8 |

Sleeve cuff

- Cuff interface

- Well distributed gathers

- Quality of cuff attachment (1/2 mark ) by impression the first stitching line

- Quality of the neatening the cuff on the WS (raw edges well tucked under (1) and well stitched down (1)Cuff ends well stitched

- (1x2) and knife edged (1x2)

- Quality of the top stitching the cuff

- Flatness of the cuff

- Evenness of the cuff width

|

1

1

1

2

4

2

1

2 |

|

|

| |

|

14 |

|

|

| 9 |

Sleeve opening

- Quality of the attaching stitchery (mark by impression)

- Quality of the neatening of the binding on the WS, that is raw edges neatly tucked under (1) and the quality of the stitches (1)

- Evenness of the binding width

- No gathers/ folds at the opening base.

- Opening base reinforced

- Binding ends concealed in the cuff. (1/2×2)

- Binding ends appropriately organized at the cuff – overlap folded (1) to WS and the under lap left unfolded (1)

- Binding edges and cuff edges flush (evenly aligned to within 2mm (1/2×2)

- Flatness of the opening when lapped/closed.

|

1

2

2

2

2

1

2

2

2 |

|

|

| |

|

16 |

|

|

| |

TOTAL MARKS |

(90/2) |

|

|

2

2

2

1

2

2

2

2

16

TOTAL MARKS (90/2)