HOME SCIENCE

Paper 2

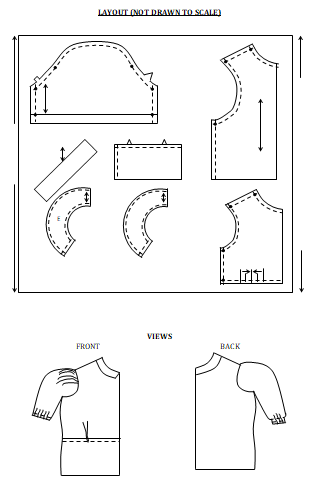

A pattern of a blouse has been provided. You are adviced to study the questions, the patterns Q the layout before you begin the test.

Materials provided;

- Pattern pieces.

A - Front bodice

B - Back bodice

C - Front yoke.

D - Sleeve

E - Collar

F - Grossway strip

- Light weight cotton fabric of 70 by 65 cm.

- Cotton sewing thread to match the fabric.

- Elastic cord 18cm long ½ cm wide.

- Envelop A4.

THE TEST

Using the materials provided, cut out and make the left half of the blouse to show the following;

- Cutting out. (15½ marks)

- Working of the inverted pleat on the front bodice. (3 marks)

- Joining the front bodice to the yoke using an overlaid seam. (10 marks)

- Joining the front bodice to the back bodice at the shoulder using an open seam. (6½marks)

- Working the side seam using double stitched seam. (7½ marks)

- Preparation and attachment of uninterfaced collar using a crossway strip. (16 marks)

- Working of the sleeve to include;

- Control of fullness at the crown. (2 marks)

- Joining of the underarm seam using a French seam. (6½ marks)

- Attachment of the sleeve. (4 marks)

- Working of elastic casing at the lower edge of the sleeve and inserting the elastic cord. Don’t seal the opening used to insert the cord. (10 marks)

- Presentation. (6 marks)

MARKING SCHEME

|

TASKS |

MAX. SCORE |

ACTUAL SCORE |

REMARKS |

||||

|

PRESENTATION |

|||||||

|

1. |

Work well pressed and well folded |

1 |

|||||

|

2. |

Label stitched on a single fabric without concelaing any details. |

1 |

|||||

|

3. |

Clearly written Name, Adm. No., Class |

2 |

|||||

|

4. |

Pins, unnecessaary tacking and hanging threads removed |

1 ½ |

|||||

|

5. |

Made up the right half |

½ |

|||||

|

SUB TOTAL |

6 |

||||||

|

|

CUTTING OUT |

||||||

|

1. |

All the seven pieces cut out. |

3 ½ |

|||||

|

2. |

Smooth cutting of the front bodice and on a straight grain. |

2 |

|||||

|

3. |

Smooth cutting of the front yoke and on straight grain. |

2 |

|||||

|

4. |

Smooth cutting of the back bodice and on straight grain. |

2 |

|||||

|

5. |

Smooth cutting of collar and under collar and on straight grain. |

4 |

|||||

|

6. |

Smooth cutting of the lower edge of front yoke and the back bodice. |

2 |

|||||

|

SUB TOTAL |

15 ½ |

||||||

|

|

INVERTED PLEAT ON FRONT BODICE (If not inverted pleat give zero) |

||||||

|

1. |

Correct size of the pleat – 3 cm. |

1 |

|||||

|

2. |

The folds just meeting without any gap and overlapping. |

1 |

|||||

|

3. |

Pleat well pressed and flat. |

1 |

|||||

|

SUB TOTAL |

3 |

||||||

|

|

|

||||||

|

|

JOINING THE FRONT TO YOKE USING OVERLAID SEAM (If not give zero) |

||||||

|

1. |

Overlay folded to the WS at the stitching line. |

1 ½ |

|||||

|

2. |

Overlay placed on underlay’s stitching line on the R.S. |

1 |

|||||

|

3. |

Seam stitched with straight and firm stitchery and close to the fold on R.S. |

1 ½ |

|||||

|

4. |

Seam turnings trimmed to 1cm and neatened together. |

1 ½ |

|||||

|

5. |

Appropriate neatening stitches used (If not, give zero from e – g) |

½ |

|||||

|

6. |

Evenness and correct tension of the stitches. |

2 |

|||||

|

7. |

Firm and neat stitches. |

2 |

|||||

|

8. |

Stitches fastened on and off. |

2 |

|||||

|

9. |

Seam well pressed and flat. |

1 |

|||||

|

SUB TOTAL |

13 |

|

|||||

|

|

|

|

|||||

|

|

JOINING FRONT TO BACK BODICE AT THE SHOULDER WITH OPEN SEAM. |

||||||

|

1. |

Seam done with firm and straight stitchery. |

1 |

|||||

|

2. |

Seam turnings should be neatened separately and appropriately. |

1 ½ |

|||||

|

3. |

Correct size of the neatened turnings 1cm to within 2mm. |

1 |

|||||

|

4. |

Seam open at the sleeve crown and the neckline. |

2 |

|||||

|

5. |

Evenness of the neatened turnings. |

1 |

|||||

|

SUB TOTAL |

6 ½ |

||||||

|

|

|

||||||

|

SIDE SEAM (Double stitched seam if not give zero) |

|||||||

|

1. |

Straight and firm stitchery of the first line. |

1 |

|||||

|

2. |

Straight and firm stitchery of the second line close to the fold. |

1 ½ |

|||||

|

3. |

Seam neatly tucked in to conceal the raw edges. |

1 |

|||||

|

4. |

Correct width 6mm to within 2mm. |

1 |

|||||

|

5. |

Evenness of the complete seam. |

1 |

|||||

|

6. |

Fell folded to the back. |

1 |

|||||

|

7. |

Seam flat on the R.S & W.S |

1 |

|||||

|

SUB TOTAL |

7 ½ |

||||||

|

|

PREPARATION AND ATTACHMENT OF THE UNINTERFACED COLLAR |

||||||

|

Preparation: |

|||||||

|

1. |

Collar joined with firm and smooth stitchery. |

1 |

|||||

|

2. |

Collar trimmed and snipped. |

2 |

|||||

|

3. |

Well knife edged. |

1 |

|||||

|

Attachment: |

|||||||

|

4. |

Collar joined to the garment with firm and smooth stitchery. |

1 |

|||||

|

5. |

Raw edges trimmed and snipped. |

2 |

|||||

|

6. |

Collar finished using crossway strip. |

1 |

|||||

|

7. |

Held in place using appropriate stitches |

1 |

|||||

|

8. |

Quality of stitches used. |

1 |

|||||

|

9. |

Fastened on and off. |

1 |

|||||

|

10 |

Correct size and shape of the collar |

2 |

|||||

|

11. |

Correct positioning. |

1 |

|||||

|

12. |

Collar flat on the right and wrong wide. |

1 |

|||||

|

13. |

Collar flashing to CB to within 3mm |

1 |

|||||

|

SUB TOTAL |

16 |

||||||

|

|

|

||||||

|

(a) |

UNDERARM SEAM (French seam - If not give zero) |

||||||

|

1. |

Straight and firm stitchery of the first line. |

1 |

|||||

|

2. |

Straight and firm stitchery of the second line. |

1 |

|||||

|

3. |

Raw edge completely concealed. |

½ |

|||||

|

4. |

Seam well-knife edged. |

1 |

|||||

|

5. |

Seam pressed to the back and flat at the casing and armhole. |

1 ½ |

|||||

|

6. |

Correct width of the seam 6mm to within 2mm. |

1 |

|||||

|

7. |

Evenness of the seam. |

½ |

|||||

|

SUB TOTAL |

6 ½ |

||||||

|

(b) |

Attachment |

||||||

|

1. |

Worked gathers at the crown. |

1 |

|||||

|

2. |

Gathers evenly distributed. |

1 |

|||||

|

3. |

Sleeve attached with firm and smooth stitches |

1 |

|||||

|

4. |

Seam allowance not trimmed and not neatened. |

1 |

|||||

|

5. |

Back notches and front notches matching to within 3mm. |

1 |

|||||

|

6. |

Seams matching where they meet at the armhole. |

1 |

|||||

|

|

SUB TOTAL |

6 |

|||||

|

(c) |

Elasticatingat the lower edge of sleeve. |

||||||

|

1. |

A narrow turning made (0.5cm) to conceal the raw edge. |

1 |

|||||

|

2. |

2nd turning made (1.5cm) to make the casing. |

1 |

|||||

|

3. |

Casing held in place using appropriate stitches. |

1 |

|||||

|

4. |

Evenness of the casing. |

1 |

|||||

|

5. |

Elastic inserted. |

1 |

|||||

|

6. |

Ends of elastic joined appropriately (i) Overlapping to 1cm. (ii) Overcasting stitches used. (iii) Quality of stitches used. (iv) Reinforced on and off. |

1 1 1 1 |

|||||

|

7. |

Gap for inserting elastic left open at 2cm from under-arm seam on the side |

1 |

|||||

|

SUB TOTAL |

10 |

||||||

|

SUM TOTAL |

90/2 |

|

|||||

Download HOME SCIENCE PAPER 2 - 2019 MOKASA II MOCK EXAMINATION.

Tap Here to Download for 50/-

Get on WhatsApp for 50/-

Why download?

- ✔ To read offline at any time.

- ✔ To Print at your convenience

- ✔ Share Easily with Friends / Students