INSTRUCTIONS TO CANDIDATES

- Write your name and index number in the spaces provided

- This paper consists of two sections: A and B Answer all questions in section A and in Section B

- Answer question 11 and any other three in the spaces provided

- All dimensions are in millimeters unless otherwise stated

For examiner’s use only

|

Section |

Question |

Maximum score |

Candidates score |

|

A |

1-10 |

40 |

|

|

B |

11 |

15 |

|

|

12 |

15 |

||

|

13 |

15 |

||

|

14 |

15 |

||

|

15 |

15 |

||

|

Total score |

|||

QUESTIONS

SECTION A

ANSWER ALL QUESTIONS IN THIS SECTION

- With respect to finishing of metal surfaces ;

- State two methods of applying paint [2 marks]

- List two reasons for applying paint on metal articles [2 marks]

-

- List two uses of drift in forging [2 marks]

- State two precautions to be observed when twisting to avoid uneven twist [2 marks]

-

- Give two reasons for using hollow metals in making furniture [2 marks]

- State four safety precautions to be observed when grinding [4 marks]

-

- List four specifications of a rivet [4 marks]

- State three factors to consider when selecting spelter for brazing [3 marks]

-

- List four methods of holding work piece on a lathe machine [4 marks]

- State two reasons for knurling [2 marks]

-

- List four sources of information for related career choice in school setting [2 marks]

- State and explain three workshop records [3 marks]

-

- Explain the purpose of annealing [2 marks]

- Outline anealing process [2 marks]

-

- State and explain three forging tools [3 marks]

- State two disadvantages of cooling a brazed joint rapidly [2 marks]

-

- State two advantages of forging over machining [2 marks]

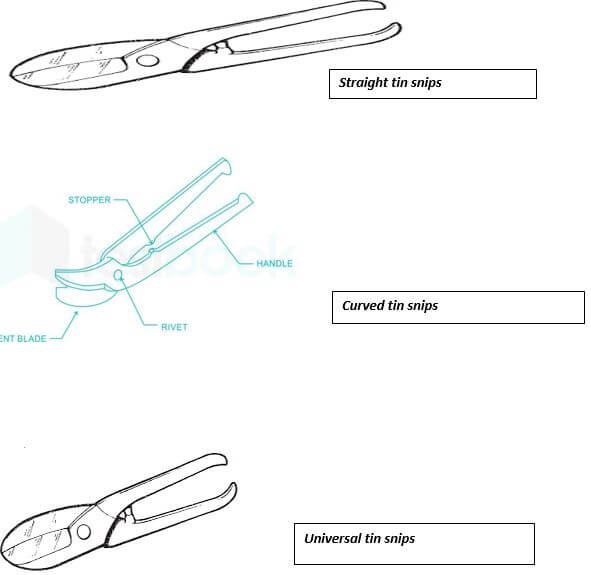

- Use sketches to describe three types of tin snips [3 marks]

- Distinguish between:

- Gross pay and net pay [2 marks]

- Change and balance [2 marks]

SECTION B: [60 marks]

Answer question 11 on the A3 paper provided and any other three questions from this section in the spaces provided

Candidates are advised to spend not more than 25mins 0n question 11

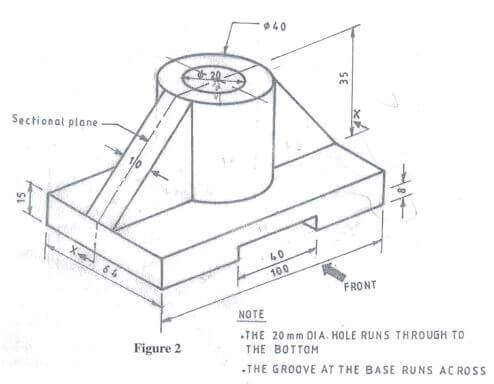

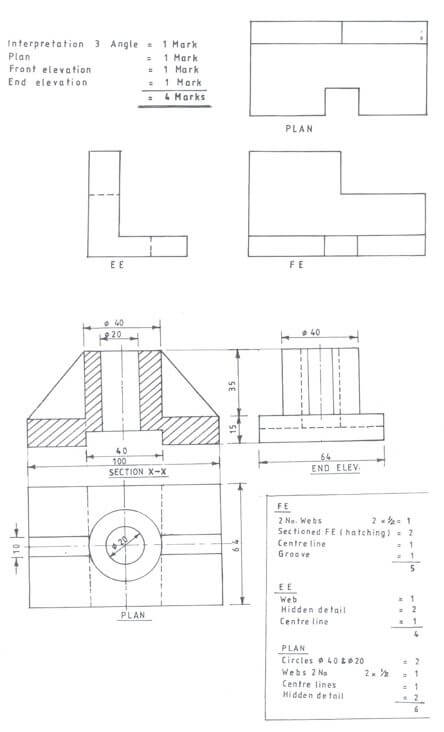

- Figure 2 shows a drawing isometric Draw the following in 1st angle [15marks]

- The front elevation through cutting plane X-X

- The end elevation

- The plan

-

- Name three methods of testing the quality of gas welded joints [1 ½ marks]

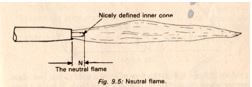

- Sketch the correct flame for welding brass and outline the procedure of setting the flame [5 ½ marks]

- Use a labeled sketch to show an appropriate technique for gas welding thick plates and give three reasons for using the technique [8marks]

-

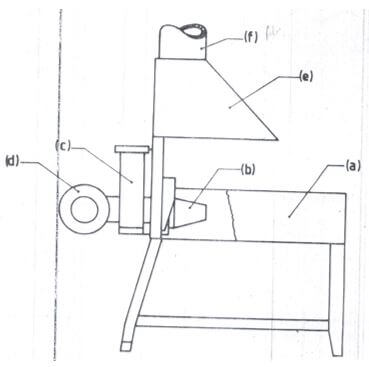

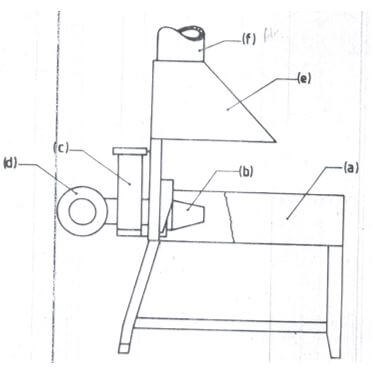

- The figure below shows a very important equipment used in forgework

- Give the name of the equipment [1 mark]

- Name parts labeled c, e and f [1 ½ marks]

- State the uses of parts a, b and d [1 ½ marks]

- List four factors that would contribute to a poorly brazed joint [4 marks]

- State three differences between gas welding and brazing [3marks]

- Give four safety precautions to be observed when tapping a through hole [4 marks]

- The figure below shows a very important equipment used in forgework

-

- Using sketches explain the following terms as applied in limits and fits [4 marks]

- Nominal size

- Tolerance

- Allowance

- Lower limit

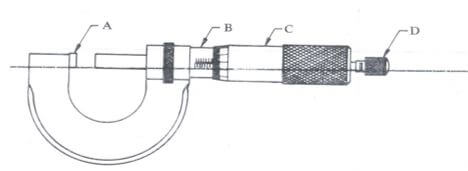

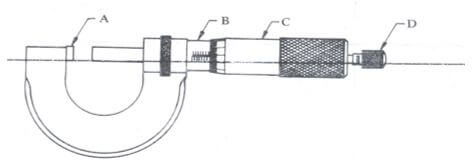

- The figure shows a precision tool used in metalwork

- Show how to find its accuracy [1 mark)

- Name the parts labeled A,B,C and D and give the function of each [4 marks]

- Give two applications of each of the three types of fits [3 marks]

- State three safety precautions to be observed when using the vernier calipers [3 marks]

- Using sketches explain the following terms as applied in limits and fits [4 marks]

-

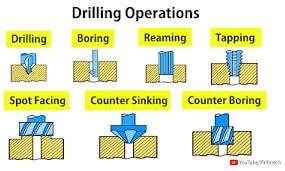

- Illustrate five operations that can be performed on a drilling machine [5 marks]

- With reference to cutting external threads:

- Name two types of dies used [2 marks]

- State two reasons for using cutting oil [2 marks]

- An M10 internal thread is to be cut in a mild steel Given that the thread pitch is 15mm, determine the size of the drill to be used [1mark]

- Give five reasons why we finish metal articles [5 marks]

MARKING SCHEME

-

- methods of applying paint

- By use of painting brushes

- By dip painting

- b)Reasons for painting

- To prevent rust

- To decorate 1×2=2marks

- methods of applying paint

-

- uses of drift in forging

- Opening up a punched hole

- Enlarging holes in forging 1×2=2marks

- precautions to be observed when twisting

- Ensure you use a two handle wrench when twisting.

- Ensure once complete twist is done in uniform heat.

- Ensure the work-piece is always straight. 1×2=2marks

- uses of drift in forging

-

- reasons for using hollow metals when making furniture.

- To ensure items made are light in weight

- For strength and durability 1×2=2marks

- safety when grinding

- Use the face for grinding and not the sides

- Always wear safety goggles

- Ensure the gap between tool rest and grinding wheel is as small as possible

- Ensure the wheel is even and balance

- Avoid loose clothing 1×2=2marks

- Switch off the machine and the power supply after use

- reasons for using hollow metals when making furniture.

-

- specifications of twist drill

- Shank diameter

- Length of the shank

- Material of the rivet

- Shape of the head 1×4=4mrks

- factors to consider when selecting a spelter

- The material to be joined

- The thickness of the material to be joined

- The position of the joint 1×3=3mrks

- specifications of twist drill

-

- methods of holding a work piece in a lathe

- By use of a 3 jaw chuck

- By use of 4 jaw chuck

- By use of face plate

- By use of face plate and dog 1×4=4mrks

- reasons for knurling

- To enhance grip

- to decorate the article 1×2=2marks

- methods of holding a work piece in a lathe

-

- sources information related to career

- News letters

- Career booklets

- Career subjects 1/2×4=2mrks

- types of inventories

- Permanent inventories -used for recording equipment tools and machines that are permanent

- Expendable inventories- used for recording items that wear out with time

- Consumable inventories- used for recording materials that are to be used 1×3=3mrks

- reasons for carrying out annealing

- To relief stress and strain caused by work hardening

- To soften metal that has been hardened by working on it 1×2=2marks

- procedure of annealing

- Heat the metal to temperatures above critical temperate, then let it cool slowly in a closed furnace 1×1=1mrk

- sources information related to career

-

- forging tools

- Leg vice- used for holding hot work piece

- Anvil -provide a platform for hammering

- Hot set- used for cutting and necking metals

- Flatters- used for finishing work piece to flatness

- Fullers -used for finishing round work piece

- Swage block -used for forming various shaped 1×3=3mrks

- state two disadvantages of cooling a brazed joint rapidly

- The joint may develop cracks

- It makes the joint brittle

- Makes the joint weak

- Causes scaling of the joint 1×2=2marks

- forging tools

-

- state two advantages of forging over machining

- Forms strong items

- Grain structures are not cut or removed 1×2=2marks

- state two advantages of forging over machining

- types of tin snips

1×3= 3mrks - disgusting gross-pay and net-pay

- Gross pay -this is the amount of money paid before deductions are made 1×2=2marks

- Net pay -payment received after deductions 1×2=2marks

-

- Name three methods of testing the quality of gas welded joints. [1 ½ marks]

- Visual inspection -Bending

- Penetrate fluid -Tensile

- Application of load. -Impact

- Sketch the correct flame for welding brass and outline the procedure of setting the flame. [5 ½ marks]

- Open the acetylene cylinder valve half turn and oxygen valve a full turn.

- Open acetylene needle valve,set to the working pressure and close the needle valve.Open oxygen needle valve,set to the working pressure and close the needle valve.

- Open acetylene needle valve slightly and light the torch.Increase the volume of gas until the flame is clear of soot.

- Open the oxygen needle valve and set a neutral flame.

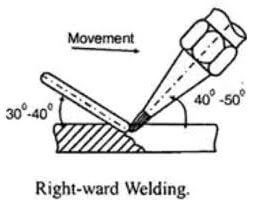

- Use a labeled sketch to show an appropriate technique for gas welding thick plates and give three reasons for using the technique. [8marks]

- It is faster than the leftward

- Less gas is used

- The cooling rate is lower so the weld is more ductile

- No bevel is required for steels upto8.0mm.

- Name three methods of testing the quality of gas welded joints. [1 ½ marks]

-

- The figure below shows a very important equipment used in forgework.

- Give the name of the equipment. [ 1 mark]

- Forge

- Name parts labeled c, e and f. [1 ½ marks]

- c-Water bosh

- e-Hood

- f--Flue

- State the uses of parts a,b and d. [1 ½ marks]

- a-Hearth-For heating the workpiece

- b-Tuyere-Protecting the blast fan

- f-Blast fan-Blowing air for the fuel to burn.

- Give the name of the equipment. [ 1 mark]

- List four factors that would contribute to a poorly brazed joint. [4marks]

- Wrong size of filler rod

- Not cleaning the area of the seam.

- Wrong type of flux

- Not arranging the parent metals well.

- State three differences between gas welding and brazing. [3marks]

Gas welding Brazing Filler metal same material as parent metal

Parent metals meld or fuse

Joint colour same as parent metal

High temperatures

Neutral flameFiller metal is brass

Parent metals do not melt.

Joint colour different from Parent metals

Low temperatures

Oxidising flame - Give four safety precautions to be observed when tapping a through hole. [4marks]

- The taps should not be given undue pressure.

- Lubricate the taps when in use.

- Use the correct size of tap wrench.

- Do not subject the taps to high temperatures.

- The figure below shows a very important equipment used in forgework.

-

- Using sketches explain the following terms as applied in limits and fits. [4marks]

- Nominal size

- Is the actual or exact size.Size before tolerance is included.

- Tolerance

- Is the difference between the upper limit and the lower limit.

- Allowance

- Is the difference between the low limit of hole and the upper limit of hole.

- Lower limit.

- Is the smallest permissible size.

- Nominal size

- The figure shows a precision tool used in metalwork.

- Show how to find its accuracy. [1mark)

- 0.5/50=0.01mm.

- Name the parts labeled A,B,C and D and give the function of each. [4marks]

- A-Anvil-Measuring face

- B-Sleeve-Has measuring graduations for the main scale

- C-Thimble-Carries the thimble scale

- D-Ratchet-Ensures correct feel when adjusting.

- Show how to find its accuracy. [1mark)

- Give two applications of each of the three types of fits. [3marks]

- Clearance-Latches,pivots,piston machines,machine tool spindles,sliding rods.

- Interference-Wheel belts,tyres,coupling under certain conditions.

- Transition-Electric motors in shafts,gear rims,fixed plugs,driven bushings,flushed bolts

- State three safety precautions to be observed when using the vernier calipers.[3marks]

- They should not be dropped.

- Always clean and close the jaws into their position and place the calipers in its case after use.

- They should be oiled to prevent rusting.

- Ensure that all the screws are in position at all times.

- Using sketches explain the following terms as applied in limits and fits. [4marks]

-

- Illustrate five operations that can be performed on a drilling machine. [5marks]

- State three reasons for twisting metal bars. [3marks]

- For strength,decoration,rigidity

- With reference to cutting external threads:

- Name two types of dies used. [2marks]

- Round adjustable split die

- Adjustable two piece die

- Solid rethreading die.

- State two reasons for using cutting oil. [2marks]

- Cooling the workpiece and the tool.

- Lubricating the work.

- Name two types of dies used. [2marks]

- An M10 internal thread is to be cut in a mild steel.Given that the thread pitch is 1.5mm,determine the size of the drill to be used. [1mark]

- 10-1.5=8.5mm

- Give five reasons why we finish metal articles. [5marks]

- To improve the physical appearance.

- To prevent rusting or tarnishing.

- To cover surface of a less expensive metal with a thin coat of a more expensive one.

- To improve the surface of an article in order to reduce or minimise wear.

- To improve safety by removing sharp burrs.

- Illustrate five operations that can be performed on a drilling machine. [5marks]

Download Metalwork Paper 1 Questions and Answers - Bunamfan Post Mock 2021 Exams.

Tap Here to Download for 50/-

Get on WhatsApp for 50/-

Why download?

- ✔ To read offline at any time.

- ✔ To Print at your convenience

- ✔ Share Easily with Friends / Students